A Quick way to cut Operational Costs Without Committing to a big Project

Have you ever wanted to find a way to cut operational costs without setting up a big project to design a new product platform? If so, this article will be interesting to you.

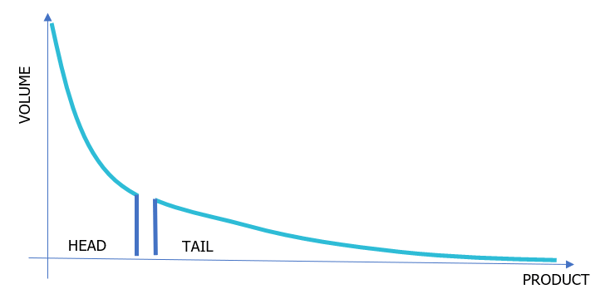

Many companies I have worked with over the years seem to have an easier time adding new products than phasing out old products. But when you add new products to your assortment, you also add cost of complexity which, in turn, hampers your company’s product quality, economy of scale and development speed. It would be nice if you could count on every new product adding substantial sales volume, but research tell us that only a few of them will. Over time, companies end up with a tail of low-volume products and higher, overall complexity.

Figure 1: A typical issue for suppliers of industrial equipment is a long tail of low-volume products. Some products can’t carry their weight of administration and supply chain investments, draining resources from the top performing products.

How to Identify Unprofitable Products?

As consultants, our primary long-term approach is to address this situation by designing configurable product platforms, aiming to substantially reduce complexity without sacrificing any customer requirements. Modularization is a long-term commitment, but actions can also be taken to secure short-term benefits.

If you simply phase-out unprofitable products, you can quickly reduce some of your complexity. The downside, compared to modularity, is a more limited impact on complexity and that you risk losing some sales volume as you shrink the product assortment.

But, phasing out products is easier said than done. How do you know that a product is indeed unprofitable? And, how do you know that phasing out one product will not lead to lost sales of other, complementary products?

To answer these above questions, you must understand:

- How much complexity is released, when you phase out the product, and what is it worth?

- How much contribution margin is lost?

- What the risk of lost sales is to key customers, and how can you manage it?

Three Steps to get you Started

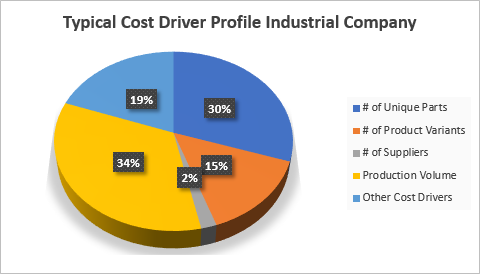

Over the years working with modularity, we at Modular Management have found that the count of unique parts is a very good measure of complexity. In fact, every unique part carries a certain amount of complexity cost which is the key to understand how much cost you can remove when phasing out the product. The below-described steps introduce the term complexity cost. This is a cost that is incurred when you design, verify, source and physically move and store the components used to build the products. The complexity cost in your company is established by breaking it down into these activities.

Let’s look at what steps you need to take in order to address the three bullets above:

Step 1. First, you must create a list of phase-out candidates -- products with low and declining sales are normally good candidates.

Step 2. The second step is to count how many unique parts each of our phase-out candidate products consume. As you phase out the product, its unique parts will disappear from production, CAD-systems, ERP-systems, reducing the cost of complexity. By subtracting the complexity cost from the gross margin of the product, you will know how much contribution margin is lost when you phase-out that product

Step 3. The final step is to analyze to what extent your phase-out candidates are sold to key customers, or if they are as a part of orders that include other products. If they do, you need to define risk mitigation measures that will go along with phasing out these products.

So, what do you stand to gain on the bottom line, if you become more successful in phasing out the right products?

Based on data that I have from numerous complexity cost investigations at industrial companies, the number of unique product variants and parts will typically drive 30-40% of all operational cost, excluding direct material (see image below).

Reduce Overall Company Cost

If your company fits this profile, and if you can manage to phase-out 5% of all your products, you can expect an overall company cost reduction of 2 % (excluding costs for direct material). Of course, every company situation is unique, but this at least gives you a sense of what to expect.

You should also consider that these savings do not take into account the positive effects of a volume increase with the remaining products. This happens when sales and customers pay more attention to them.

Overall, you have the opportunity to quickly improve your margins by following the above steps to selectively phasing out products to prune the product portfolio.

Help to get started

If you are interested to know which of your products are candidates for phase out, I’m happy to spend an hour with you getting started. Send me an email and let's find a time to talk.

AUTHOR

Karl Bråtegren

Senior Manager

T: +46 8 456 35 00

E: karl.brategren@modularmanagement.com