Since the Industrial Revolution, individuals have come to expect increasingly customized products. The speed of innovation is increasing, driven by digitalization and the fight for sustainability, while commoditization and globalization are pushing down prices faster than ever before. How can companies employ the features of agility and customization to gain a competitive advantage? How can they leverage economies of scale and reduce the cost of complexity without impeding innovation? And lastly, how can they provide customers with the seemingly opposing benefits of both customization and industrialization?

Modularization is a tool to subdivide the product in a logical way that provides both economies of scale and the ability to create different configurations for increased value for customers. The Modularity of a product is a measurement of how configurable it is, meaning how many combinations you can build with a given number of building blocks.

Working with a Modular System is a mindset. It can be leveraged across all industries, pushing the boundaries of what can be achieved with product platforms and shared components. Masters of the art of modularization acknowledge that it is much more than just a modular product. Modularity encompasses the whole business; Products, Operating Models, and Infrastructure.

Modular Systems are not limited to product-focused industries such as cars, home appliances, or telecom. Modular Systems are also imperative for transforming project-oriented businesses from Engineer-to-Order to Configure-to-Order operating models. Modularity is also a springboard for service-producing companies to control the offering, and to transfer both knowledge and value from individuals to the organization. Modularization is a fundamental tool within software development to increase code reuse, enable parallel development, and reduce testing effort.

Below we will share our thoughts on what a Modular System is, how to use modularization to enable your business strategy, how to create a system for your products, and how to improve it. We will also share how to measure modularity and what core capabilities are needed for success.

What is Modularization?

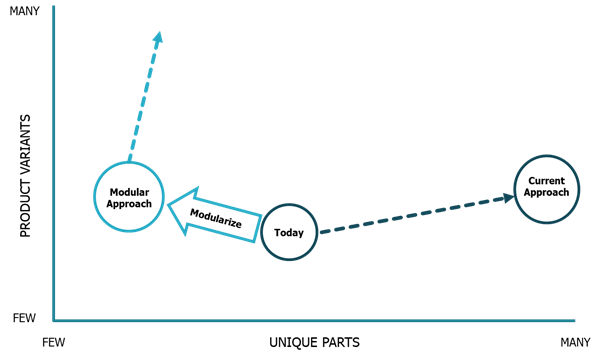

Modularization is the activity of dividing a product or system into interchangeable modules. The target of modularization is to create a flexible system that enables the creation of different requested configurations, while also reducing the number of unique building blocks (module variants) needed to do so. By re-using module variants across multiple configurations, volumes are consolidated on the module level, and economy of scale is reached without limiting/rationalizing the product offerings.

The benefits of a modularity approach are many. For example, a company can increase customer value by configuring the right product for the situation. The speed of development is increased because innovation is limited to one or a small group of modules in the system rather than a whole product. Additionally, internal complexity is reduced by limiting the number of variants to design, manufacture, and maintain the portfolio. This internal cost of complexity is often overlooked or widely underestimated in enterprises because it takes so much time, resources, and capital to maintain large numbers of parts.

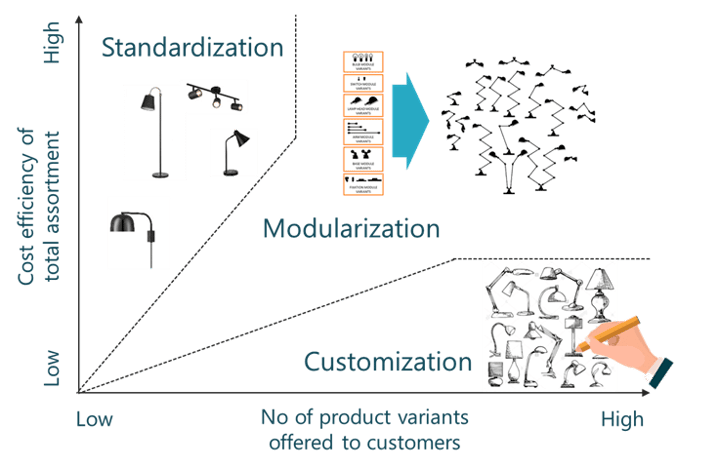

Modularization combines the benefits of standardization, which drives a low cost of complexity, with customization by creating the right product for each customer and their situational needs.

Modularization captures the benefits of Standardization and Customization

While the most obvious examples of modularization might be physical products, the technique is just as useful within software and service products.

The main enabler of modularization is standardized interfaces. The interface allows one variant of a module to be interchanged with other modules to meet the required performance level and adapt to specific applications and/or functional needs of the product.

What is a Modular System?

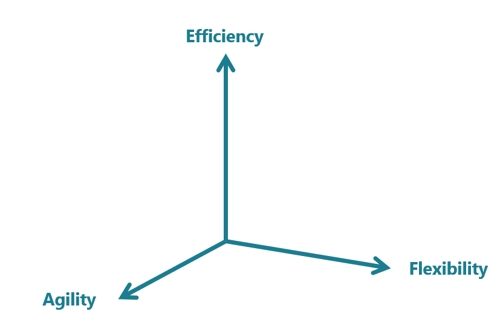

A Modular System is a group of modules, interfaces, and rules that enables the configuration of products. Success is built upon the ideas of flexibility, agility, and efficiency. A great Modular System will enable efficiency, of course, but it will also be flexible for a large scope of products and agile for future changes so the architecture can live for a long time. Read this post to gain further insight into what defines the best modular systems.

Efficiency for a Modular System means enabling an economy of scale and stability. By re-using modules across different products, volumes are consolidated. By isolating modules when changes are required, supply chains can benefit from long-term plans and commitments. For example, a battery system may include a cooling fan that can be common across all product variants. In our experience, this is the first trait of modularization that industry executives recognize.

Flexibility for a Modular System means enabling mass customization for specific customer needs. As an example, a battery system may be configured to provide different energy storage capacities. For SKU-driven businesses, Modular Systems enable faster SKU creation with less effort. For customized products, modularization helps highly efficient configuration tools to make quotes faster and more accurate. In many cases, the customer can configure the product herself in an online CPQ (Configure-Price-Quote) system.

Agility for a Modular System means allowing for swift and controlled changes for new requirements and/or technologies. For example, the charge control electronics may be upgraded to allow for optimized charging considering speed and green energy availability. By preparing for a change in geometry and interface specifications, changes can be isolated to specific modules, enabling the surrounding modules to remain untouched.

Companies that succeed in creating Modular Systems, systems that tick all three boxes, outperform the competition regarding customer value and cost. It affects the whole business; Sales, R&D, Production, Sourcing, After Market, and everywhere else where the product complexity impacts margins, costs, and speed.

What is Modularity?

Modularity is a measurement of how well a system performs given the business strategy and targets set. Those targets can generally be defined as efficiency, flexibility, and agility. Thus, the measurement of modularity will vary with what is most important to the specific business. Some measurements will be more important than others given the targets set for the modularization program.

To measure efficiency we can create a measurement of how many different building blocks are needed in the system. The fewer, the better. An excellent proxy for efficiency is part number count (PNC). By controlling part number counts, managers can ensure that complexity is not added over time unintentionally. It also becomes much easier to measure the impact of any new parts that are added intentionally to expand share or improve the offering. In many companies today, PNC expansion/reduction and its impact are poorly understood, leading to margin decline.

To measure flexibility we can use a measurement of how many configurable products are available to sell given a fixed set of module variants. This measure is often called configurability and defines as the number of possible products divided by the number of components (PNC) needed.

To measure agility we can measure the number of new components required to increase the product offerings. This is typically measured over a period to get an average reading, for example annually. The definition of the metric is the number of introduced components divided by the number of enabled product variants.

Chart illustrating how modularity is creating flexibility while reducing complexity

Leif Östling, former CEO of Scania, has said:

“Control and limitation of part numbers is one of the most important factors to optimize profitability over time.”

The History of Modularization and Modular Systems

While proof of Modularization can be traced as far back as the Terracotta Army (200 BCE), modern industrial use of modularization was pioneered by leaders in different industries such as Scania, Toyota, Nippondenso, Dell, and Sony. These companies managed to take clear market leadership using modularization, governing, and improving their Modular Systems over time.

In Germany, modular systems are often called Baukasten, a term literally translated to construction set. Volkswagen, for example, calls their modular systems Baukasten, e.g., Volkswagen MQB, which stands for Modularer QuerBaukasten, roughly translated to Transversal Engine Modular System. Baukasten was frequently used as a term in the 1930s for do-it-yourself kits, such as model railways, modular radios, and electronics toolkits for kids. These toys have much in common with industrial modular product platforms. They have the same target to create flexibility and the same means - standardizing interfaces.

Sony utilized modularization in a structured way for both the Handycam and Walkman product lines to continuously stay ahead of the competition throughout the 1980s. As soon as competitors caught up, Sony could immediately launch the next version and again be the product leader.

Scania, on the other hand, understood that modularity was the way to enable mass customization. By creating a modular system for the truck on different levels, an almost infinite number of variants could be configured and manufactured on the same assembly lines without costly changeovers. For decades Scania’s unique focus on modularity enabled them to outperform the competition in profitability (2X to 5X), even though their volumes were lower than some competitors. By optimizing variance and customization, Scania successfully reached an excellent economy of scale while simultaneously providing individual drivers with the exact truck they desired.

Within electronics a great example of modularization are the PC form factors of PC/AT (developed by IBM in the 1980's) and ATX (developed by Intel in the 1990's). These interface and form factor standards enabled the users to configure their own PC's according to their needs and preferences. Electronics modularization can act on many levels, physically as well as logically.

In today’s modern economy, successful companies are champions of modularity in hardware, software, products, and services. With the birth of Web 2.0, modularity reaches across company barriers. Today, micro-services, web apps, and open APIs enable a whole new set of customization possibilities. And as more functionality transitions from hardware to software, traditional hardware companies can also benefit from adopting new ways of thinking and working.

Improve Quality, Time-To-Market, and Enable Scaling with Software Modularization

Many companies suffer from complex software development such as:

- Difficulty in scaling the development capacity

- Software is driving quality problems even though the testing efforts are high

- Difficulty in planning and budgeting software development since changes lead to unforeseen ripple effects

Three typical root causes for software architecture problems are “Developed by me” software, highly coupled software structures, and multiple overlapping software platforms.

Even companies that traditionally have been focused on mechanics are becoming software companies whether they like it or not. CTOs of “hardware companies” are realizing that they often have more software engineers than hardware engineers.

By making software modules independent, reusable, and interchangeable, development can be much more efficient and truly agile. Independent modules make development teams autonomous for improved efficiency and time to market. Read more about Strategic Software Modularization and download our template for documentation of a strategic software module.

Terms to Know Regarding Modularization and Modular Systems

Module

A Module is a functional building block with specified interfaces driven by company-specific strategies.

Modular System

A modular system is a collection of building blocks that can be configured in different ways, adapting to different customer needs. Modular Systems can be hierarchical because modular sub-systems can be shared across more than one modular product architecture. Modular Systems can have one or more architectures which are the structures that describe how products are built with the modules.

Modular Product Architecture

A Modular Product Architecture is a geometrical and logical structure for building a type of product based on a Modular System. For example, a company can use one Modular System for both washers and dryers. However, the washers and dryers have different Modular Product Architectures.

Modularization

Modularization is the activity of subdividing a system of products into modules. Modularization can act on any combination of hardware, electronics, software, and services.

Module Variant

A Module Variant is the realization of a Module, fulfilling its interfaces and strategic intention. For hardware and electronics, it is a physical part. In software, it is an encapsulated piece of code. Software modules typically have only one realization that is flexible for all use cases. For hardware and electronics, each module will have one or more variants.

Module Interface

A Module Interface defines how a Module interacts with its surroundings. The interface can be with other modules, but also with the external world. An interface can be physical, attaching one module to another. It can specify how information, media, or power is transferred between two modules. It can also be geometrical, defining the space reserved for the module.Configuration

A Configuration is a specific combination of module variants according to a Modular Product Architecture that fulfills a set of configuration rules.

Configuration Rules

Configuration Rules govern how a product is allowed to be combined from a set of module variants. The Modular Product Architecture describes structure, how the product is built. The Configuration Rules describe the logic for what module variants can be combined and define how customer needs are translated to a suitable configuration. Configuration rules can also control business logic. For example, the packaging and the pricing of products and features.

Product Configurator

A Product Configurator is a software solution that executes configuration rules. It can be customer-facing in the form of a sales configurator/CPQ solution. But a Product Configurator can also be used internally to create bills of material for production, and engineering, or to automatically generate drawings for customizable products.

Cost of Complexity

The Cost of Complexity is used to describe the expenses caused by introducing new offerings and managing the variety of products produced. Many different products would cause a high cost of complexity. Whereas fewer and more similar products result in a low cost of complexity. In essence, it is a way to understand the economy of scale and how products affect it. Modularization can be used to improve the economy of scale while keeping configurability in the products. Scale is reached on the module level rather than on the product level resulting in a better market offering with far fewer parts.

Platform

A product platform is a collection of similar products that are grouped to enable cross-product sharing of certain components. Product platforms often can become rigid and inflexible when new or different customer adaptations are required. Platforms are also more difficult to enforce the re-use of components across product lines. Note: Modularization and a Modular Platform can be used as a synonym for a Modular System. Volkswagen is a great example of transitioning from products to platforms to modular systems.

Three Great Examples of Modularization and Modular Products

Example 1: Husqvarna Electric Trimmers

The Husqvarna organization is exemplary in many ways. Not only in the forest but also in the field of modularization. One example is the modular system for electric trimmers. Multiple brands and an evolving array of SKUs share the same architecture, supporting the transformation from corded trimmers to battery-powered.

This illustration shows how a modular system can be flexible enough to differentiate brand characteristics without losing scale benefits in functional parts. Components such as motors, batteries, speed control, and cabling can have substantial scale advantages. And when the commonality can even be made on the sub-assembly level, it opens up possibilities for sourcing larger, pre-tested assemblies.

Other great examples from Husqvarna can be seen in robotic mowers where multiple brands share architectures, while configuration rules and styling modules separate brands and price points.

Husqvarna is also pioneering in using IoT and cloud solutions to push the business model from selling hardware and consumables, to selling gardening tools as a service with their Tools for You concept. IoT is also used for professional fleet management.

Example 2: Wärtsilä 4-Stroke Engines

Wärtsilä produces enormous engines and they have a vast portfolio. They produce relatively small engines (around 200 mm cylinder bore) used in auxiliary or diesel-electric power generators to huge powerhouses (500 mm+ cylinder bore) used in power plants and direct drives on ships.

Requirements are high regarding flexibility; custom machine room layouts, fuel types, power requirements, and operational patterns, just to name a few driving forces. At the same time, technology is pushed by competitors and even more by the continually increasing global sustainability requirements. Wärtsilä’s modular 4-stroke engine system is prepared to take on this challenge.

Here are two great examples of modularization from Wärtsilä:

- By making the engine block flexible with respect to the positioning of the main power take-out shaft and the turbocharger assembly, machine room flexibility is reached without duplicating complexity.

- By creating standardized interfaces between fuel injection systems and cylinder heads, fuel types can be configured without affecting the engine’s fundamental functional parts.

Wärtsilä 31 is the most fuel-efficient 4-stroke engine available on the market which is great for the operator and great for the planet. Read the full case story of The World's Most Efficient Engine.

Example 3: Spotify Web API

By publishing a public API that any developer can use, Spotify is pushing the barrier and limits of its product.

Even greater products are created by infusing Spotify modules, such as Albums, Libraries, and Playlists. This open access means that Spotify can rapidly become an integrated part of Smartwatches, Smart speakers, Car entertainment systems, TVs, and so on. These developments would never have been possible at this rate without cooperation. The key here is standardized interfaces.

By publishing well-specified and stable interfaces, the development can be made concurrently on both sides of the interfaces, completely without communication. This concurrent development is the same effect that modularization brings to a company. However, the challenge of specifying the interfaces may be even more critical. If care is not taken, businesses may end up maintaining many different generations of their APIs.

What’s great about the Spotify example is that it removes the organizational borderline for global cooperation. Modularization does not have to be an internal strategy only.

Four Fundamentals for Modularization Success

A chain is no stronger than its weakest link. To reach sustainable success within Modular Systems, you must ensure strong competence in four areas.

Modular System Strategy

Understanding how your Modular platforms are supporting the business strategy is fundamental for success. Without alignment on present challenges, future visions, and what path you are on, you will only reach a fraction of your true potential. Alignment must start from the top and ripple down in the company.

Alignment must be secured top-down for how to:

- Connect Business Strategy to Product Architecture Strategy

- Organize and focus on Innovation

- Understand the Business potential of modularization

Product Architecture Strategies may be very different across companies and business areas. One example is the construction industry’s trend to use modular building systems to move from project-based to configuration-based construction. The target is two-fold; to improve customer value and increase efficiency. Each business needs to correctly understand where they are against these benchmarks and what are their goals to maintain efficiency while growing. A tool to analyze this is the Product Architecture Maturity Model. Read the article linked below to learn more and to complete a quick, online self-evaluation.

Another example is the fight for sustainability. How can Modular Design help companies embrace the circular economy? Modular Management partner Colin de Kwant is researching the topic in cooperation with the Royal Institute of Technology.

Modularization: Creating a Modular System

To create a Modular System organizations must understand what needs the products fill, how these needs might change over time, and what performance levels must be reached to satisfy customers. Market models should be created to ensure that the right focus and prioritizations are established. Tools that can help this understanding and prioritization fall under the topic of Needs-based Market Segmentation. Scott Jiran has written a blog post on Customer Canvas as a tool to analyze customer benefits of different segments to help you see one output of this process.

The best Modular Systems are both flexible and agile. Creating this synergy requires a deep knowledge of the product and its current technology, while also comprehending how it must be adapted and developed to produce the needed functionality and performance levels required for the application.

But understanding the technology is not enough. There must also be an understanding of how business strategies across all functions can be enabled by the product structure. One example is how lean production is enhanced by implementing a modular product architecture. This link, implement lean and modularity, shares how to gain synergies between lean production and modular product architectures.

Understanding the needs of the market, technology, and business is a great start for modularization with the right flexibility and agility. But to ensure that re-use and long-term governance can be achieved, the modules and interfaces must also be designed and documented to enable the architecture intention to be sustained.

Improving a Modular System

All companies that have products in production have a Product Architecture, be it modular or not. This means that all companies can improve their existing architecture.

Incremental improvements, continuous improvement, rapid process improvement, and Kaizen are some of the many names for making a process better. This is also one of the key properties of a great modular system—it lasts for a long time and therefore can be improved.

There are many topics of interest in the area of improving Product Architecture, some examples include:

- Prioritize R&D and align phase-in/phase-out plans across the company

Cutting the tail of unprofitable products, taking cost of complexity into account. - Identifying and prioritizing candidates for redesign, optimization, and value engineering

Set targets, act, and follow up. - Identifying and prioritizing supply chain actions to reach Procurement Excellence

Consolidate volumes, align module, and supply chain strategies. The Covid-19 pandemic has also increased the spotlight on resilient supply chains even more. How can modularization enable geo-flexibility and dual sourcing?

Core Capabilities Needed to Succeed with Modularization

The fourth and last fundamental is the core capabilities of the company. No matter how good your product is, you will fail if you don’t have the capabilities in place to utilize and maintain it, including:

- Processes, roles, and decision models to achieve efficient modular system governance, design, sales, sourcing, and production.

- Improve efficiency from sales to delivery & development, while maintaining processes with digital solutions for sales, product management, R&D, and supply chain management. Companies today are already digital, but how must the systems be adapted to move from products to Modular Architecture? One example of utilizing modular platforms in the sales system is implementing guided selling tools or configurators.

- How to understand the cost of complexity and balance re-use to direct the cost in architecture and design decisions.

Lars Gullander has written an informative piece titled, How to Manage Change in your Modular Product Architecture? In it, you will also find examples of decision models for governance.

Six Tips and Reminders for Modularization and Modular Systems

Succeeding with a Modular Transformation program is a long-term cross-functional commitment. In this section I will share six tips on critical success factors. On top of this, my colleague Thomas Enocsson shares his true-life experience on how modularization transformed one of the largest product development programs in Europe.

Tip 1: Always Start with the Customer

The most crucial input when designing any product is to understand how to create value for the customer. This is even more important when designing a Modular System since the goal is to make a product flexible enough to satisfy your customers, while also ensuring that the product has a long lifecycle. This means an understanding of the whole range of requirements and how they may change over time. There are many tools available to help you, including needs-based market models and innovation scoping.

Tip 2: A Cross-Functional Effort to Design

A modular system promises benefits across the majority of internal organizations; sales, marketing, product management, R&D, procurement, logistics, production, after-market, and many others. To ensure maximum benefits, it is fundamental that the functional “voices” and expertise influence the modular system design. This enables maximum benefit realization by leveraging opportunities within each function and making tradeoffs balanced by key functional perspectives. This style of implementation leads to optimal decision-making with a respect to the architecture. If one function starts to change the system without involving other internal organizations, there is a high risk of deterioration.

Tip 3: Be Committed to the Long Term

Rome wasn’t built in a day. Companies with large and complex portfolios in production should not endeavor to transform overnight. Successful companies have proven that winning the complexity battle is a marathon rather than a sprint. Start small, create a great example, and change incrementally over time. The most important principle is to go in the right direction. Great results will naturally accelerate the pace as you learn.

Tip 4: Know the Value of Modularization

Creating Modular Systems takes commitment. Taking time at the start to understand the cost of complexity and rallying the team around the right goals may feel like a delay, but it is crucial for avoiding additional costs and time to launch when the detailed design work begins. This means decisions must be made that may go against traditional decision mechanisms. For example, many companies focus on direct costs only when making product design decisions. They miss the equally large, and often larger, value creation opportunities in revenue growth and reduction in the cost of complexity.

To make such decisions, prioritize the best resources to design your modular platform and remain firmly committed over time. It is crucial to understand the value of modularization clearly. How will modularization affect your income statement and balance sheet? How will you gain more profits? By agreeing on a fully developed financial target, the management team can stay committed.

Tip 5: Get Ready to Govern the Modular System

The value of a shared modular system doesn’t show as money in the bank from day one. It is a vehicle for long-term success. To be successful, we must guard the system over time. Make sure from the start to adapt governance models, decision forums, and product owners to act on modules and architecture rather than products. When should you accept change? When should you refuse? Who makes the decision? On what grounds?

Ensuring that you have a clear alignment on these tough questions from the beginning creates the best possible foundation for your investment to be profitable over time.

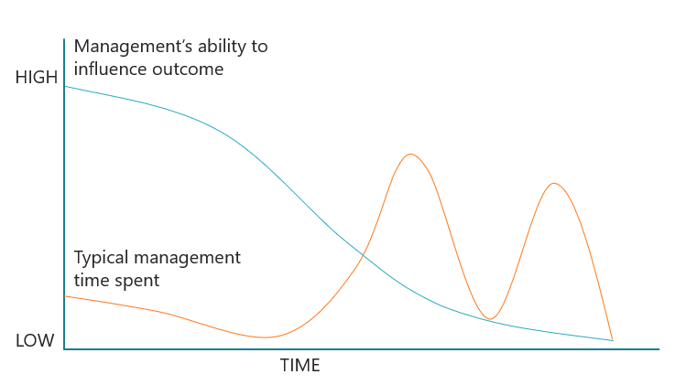

Tip 6: Ensure Early Management Commitment to Modularization

Change Management teaches us that leadership’s ability to influence a positive outcome is greatest at the beginning of any initiative. Yet, a common mistake is for management to not be involved until it is too late to provide positive input. Management’s involvement should not only be at the toll gates. Setting up a Modular System is a significant change in mindset for the company. Management must be committed and involved from day one.

Modularization in a Changing World

Modularization isn’t just a product strategy — it plays a key role in how companies respond to external shifts like tariffs, supply chain disruptions, and changing market conditions. A modular system allows companies to reconfigure what they already have, rather than start over. This capability doesn’t just reduce cost and lead time, it enables strategic decisions to be executed faster across manufacturing, sourcing, and commercial functions.

In this context, modularization becomes the foundation of composability, an approach where flexibility is built into the entire business. For a closer look at how modular thinking supports resilience in uncertain times, read our blog on how companies thrive through tariffs with modularization and composability.

Talk to us about Modularity

Since 1996, we have focused 100% of our attention on helping businesses worldwide improve with Modular Systems. We know that with modularization, ways of working, and the tools to support it, you can simultaneously reduce complexity and enhance value.

We are always interested to hear your story and discuss how we can help your organization reach its goals. Let us be your sounding board! You can reach out to us today.