Sell More, Faster, With Less Effort!

Henry Ford once said, "Any customer can have a car painted any color that he wants as long as it is black." What was once a fundamental enabler for industrialization can feel far away today, where mass customization, modularization, and online product configurators are taken for granted by businesses and consumers alike.

Today customers want to configure their own individual solutions. They don't want a standardized package but a solution that meets their specific needs and preferences. The challenge is to enable this in a process that puts the customer in the front seat but doesn't overwhelm the business with complexity.

Imagine walking into a car dealership. The salesperson greets you nicely and asks some questions about you and what specific needs you have. A good salesperson will tailor the following questions based on each response and utilize all the available information. By asking relevant questions, you feel that the salesperson understands your needs and cares about finding the perfect solution. After a brief conversation, the salesperson presents a car that fulfills all your wishes, including the budget constraints. Of course, the suggested car is one that the dealership can supply and deliver within your required timeframe.

The salesperson is performing the main function of product configuration: understanding the customer's needs and proposing an attractive solution that fits those needs.

The salesperson is performing the main function of product configuration: understanding the customer's needs and proposing an attractive solution that fits those needs.

The imaginative example is a basic description of a salesperson's primary task, initializing the sales to delivery process: meeting potential customers, understanding their needs and requirements, and what is needed to win the order. Translating this into an offer that fulfills the customer's expectation and fits with the business objectives and capabilities of the company is a core competence of any business.

What the salesperson is doing is also an example of product configuration. In this blog post, I will explain further what Product Configuration is, then move on to analyze for what types of businesses product configuration is relevant, looking into different types of configurators, and how to enable configuration within design engineering, supply chain, and IT systems. I will finish by exploring different types of software for product configuration and looking at some of the main benefits of product configuration.

What is Product Configuration?

Product Configuration is the function of selecting and arranging parts in a combination that can be produced and delivered to fulfill a specific customer request. Product Configuration can be performed manually by a salesperson or a sales engineer or automatically by a software solution.

Product Configuration is different from tailoring in how the configuration is prepared – the questions asked and the selection and arrangement of parts follow a predefined logic allowing other business functions to be well-prepared for efficient execution of the order.

Product Configuration is different from a sales catalog in that the selection is interactive. The salesperson or configurator asks questions and either ask further questions or suggests an attractive solution based on the replies. No complete solution or combination is defined in advance. The offered solution and combination are a result of each specific combination of needs and responses.

Is Product Configuration Relevant for all Market Approaches?

Depending on the how you market your assortment, product configuration will be used differently. Some companies will only use it as an internal tool to generate BOMs, and some will use it to support salespersons. Some will even use it at the front end, replacing the salesperson and making the configuration process self-service.

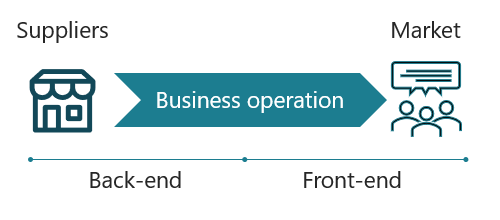

We like to separate between three different market approaches: Product-based, Configuration-based, and Project-based. For each market approach it is critical to align the back-end ways of working and tools to benefit from product configuration.

The front end is where the company markets, sells, and delivers its products. The back end is the company's internal workings and inbound supply chain.

The front end is where the company markets, sells, and delivers its products. The back end is the company's internal workings and inbound supply chain.

Product Configuration for Different Types of Businesses

1. Product-Based Businesses

Product-based businesses market a list of fixed products, traditionally in the form of a catalog. There is no real need for a configurator in the front end of the sales process since the products are already predefined. The primary requirement for a sales configurator, in this case, is to select the right product. It can act as a tool for guided selling, much improved over a traditional catalog.

In the back end, a configurator can be used by R&D to create the BOMs in the first place. Suppose many products are made from a modular product platform. In that case, a configurator could ensure that all the products are valid and optimal combinations of modules.

2. Configuration-Based Businesses

The configuration-based business treats each order as unique. The customer will be presented with choices in the front end, either of needs or preferences or components and packages. The front-end configurator, in this case, must present the right questions and translate the answers to a suggested solution that is valid.

In the back end, things can start to become more complicated. A BOM must be generated on the fly to enable the next step in the order to delivery process. Depending on the nature of the business, this can be complicated. One such complication is if there's a need to customize the product, then the BOM must typically be created in the PLM system to be customized and then transferred to the ERP system for production. Another complication is handling the actual BOM structure in the PLM and ERP. If the products are highly dynamic in nature, they can be complicated to represent in the systems depending on the systems' capabilities to handle dynamic BOMs. The result might be many Super BOMs, sometimes called 150% BOMs. These Super BOMs are complex to maintain.

But even if there may be challenges – Product Configuration is a crucial enabler for mass customization. The alternative is to have fixed products and sell them in a configurator presenting endless variation. This scenario is much worse since it will explode the product-level complexity that is maintained internally.

3. Project-Based Businesses

In the project-based market approach, the business is focused on delivery projects. Many manhours are spent on engineering each delivery, and since each solution is tailored, it is challenging to leverage continuous improvements, reuse, and consolidated volumes.

However, there are repeatable bits and pieces in most project-based businesses, and those could be supported by the product configuration of a central building system governed separately from the projects.

If product configurators are used in the front end, it is preferable to have an unbroken digital thread to the back end to ensure consistency and efficiency.

In the back end, the product configurator can be part of creating the BOM in the PLM (or BIM for construction) system.

Different Types of Product Configuration

Depending on the nature of the sold product, the configuration problem could be either Geometrical (how to position items), or Functional (what items to use), or a mix of both.

Geometrical

Geometrical configuration is about positioning objects to create a layout of e.g. a production line. The layout must fulfill given rules of functionality (e.g. have the right production sequence). The layout must also be free from collisions, both internally in the configured product, but also with any existing objects such as pillars, other equipment, etc. A typical task of a geometrical configurator is also to adjust parametric objects, perhaps to bridge the gap between two machines with a conveyor.

CAD software with predefined functional blocks or a geometrical configurator could be the tool to use.

Two examples of publicly available geometrical configurators are IKEA's Kitchen Planner, and Elfa's Storage Planner.

Geometrical configurators typically give instant visual feedback on the validity of the layout.

IKEA's Kitchen Planner is an excellent example of a geometrical configurator. Like most geometrical configurators, it also performs functional configuration of the positioned items.

IKEA's Kitchen Planner is an excellent example of a geometrical configurator. Like most geometrical configurators, it also performs functional configuration of the positioned items.

Functional

Functional configuration is about selecting a correct solution given a set of requirements or needs. Based on the required performance, functions, and features, the configurator selects and dimensions the different parts of the products (modules) and ensures that they are compatible and that the combination of parts performs according to the requirements. The input to the configurator can be needs-based, e.g., enter your electricity cost and get the optimal configuration. The input can also be solution-based, where the input is a selection of available variants or options, and the user must decide the best choice.

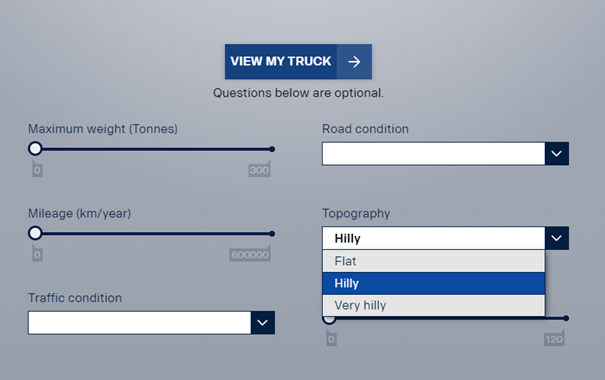

An example of a publicly available functional product configurator is Scania's truck configurator.

Scania's Truck Configurator is a nice example of a functional configurator.

What is Configurability?

Configurability is a measurement of how suitable the product is for configuration. It is primarily linked to:

- How the product is designed and structured.

- How the supply chain is set up to support a configurable product.

- How the product is represented in IT systems

When understood together, configurability and configuration enable the mass customization of products to meet specific and individual customer needs efficiently and effectively.

Design for Configuration

To create configurable designs, products should be flexible enough to allow for the adding, removing, or replacing of elements without impact across the product. Changes must be isolated to the directly customized element, without causing indirect changes to surrounding elements.

A modular design has exactly this ability. Why? Because functions, features, and performance levels are encapsulated in individual modules and the modules themselves are protected from each other by interfaces. This allows one module, or variants of one module, to be changed while still fitting the interface, without changing any other module. The more modular the product is, the easier to configure.

A modular product will always be configurable. However, the opposite is not necessarily true, a configurable product is not necessarily modular. For this case, setting up the configuration model will be much more complex and harder to maintain since the different products will likely have different logics. And components will be product-specific rather than reusable across different products.

We have gathered a list of common CAD systems that supports configuration design, you can download it here.

Configurable Supply Chain

Setting up the product design for configuration is not enough if the supply chain is not prepared to handle the flexibility.

Many traditional industrial supply chains are set up to make products to stock. Batching, low-cost country sourcing, and dedicated lines are concepts that make standard products more efficient to produce – but these concepts are not flexible to handle mass customization.

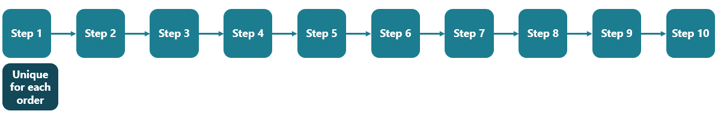

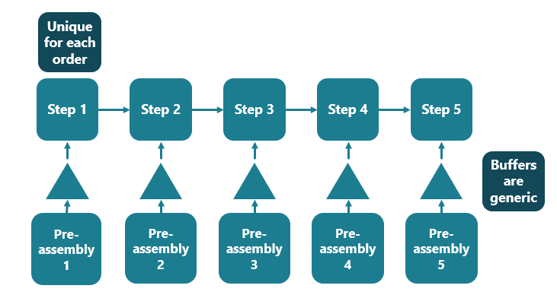

Imagine a supply chain with 10 process steps. If the unique customer request affects already the first step, nothing can be prepared in the advance. The product cannot be delivered until all 10 process steps have been carried out.

In a process where the first step is unique for each order, the whole process must be carried out before the product can be delivered.

In a process where the first step is unique for each order, the whole process must be carried out before the product can be delivered.

To solve this, we need to delay the point of variance. This is the point in the supply chain where parts and assemblies become a unique order combination, instead of generic parts that could fit into multiple combinations. By delaying the variance point, all assembly operations that make the combination order unique are delayed until the order is received. At this point, the requested combination is known and assembled to order. Only generic parts up to module level are purchased or produced to stock, before the order, and are then ready to be assembled in the correct combination.

By pre-assembling generic parts that could fit in multiple configurations, the order-to-delivery lead time can be drastically reduced. The point of variance has been moved later, and there are only five steps to carry out before being able to deliver the product.

Product Configuration and IT Systems

A customizable product needs to be represented in IT systems so that elements can be easily added, removed or replaced.

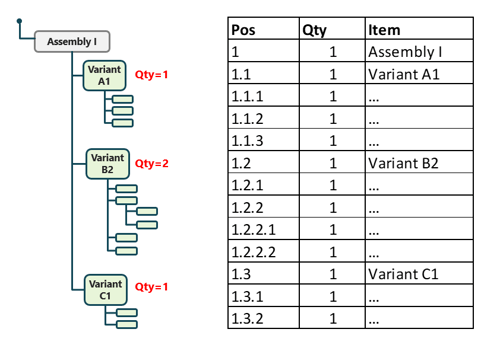

One important aspect of configurability is the level at which parts are documented in the bill of materials (BOMs). Many companies sub-optimize the BOM to simplify or reduce part number count. Parts are then documented on a too high level, and above the level at which customers want to add, remove, or change elements. This means that only predefined combinations of elements exist, and no unplanned combinations can be made. Over time, the goal of part number count reduction becomes harder since the number of combinations needed grows exponentially with a multiplication effect. At this stage, companies are still only making predefined combinations and configurability suffers.

Two representations of the same multi-level BOM: Graphical and tabulated

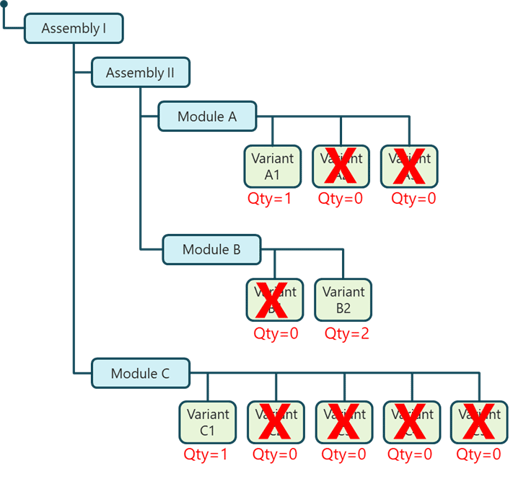

Another important aspect is how to manage the total configurable product range in terms of the bill of materials. Do you have multiple super BOMs for different products? If so, this means you can make changes inside one super-BOM, e.g. add, remove or change elements, but for other changes, you have to change to another super-BOM and throw away what you just did, open up a new super BOM and start from scratch. A truly modular BOM, on the other hand, can handle the full range of products. In the following section, I will further explain the importance of efficient product structure.

Importance of Product Structure to Enable Product Configuration

For all non-product-based businesses, it is key to not let the back-end systems work with fixed products, while the front end works with dynamic configurations. From the sales side, we would like to get a competitive advantage from flexibility. Therefore it will be crucial that the internal processes are set up to handle flexibility without being overwhelmed. This brings a challenge to the traditional product structure, where a BOM is the basis for a product. How can we efficiently generate the information needed to produce the order?

Many existing systems used in the industrial operation rely on having BOMs that are fixed to be able to generate plans for material purchasing, assembly, etc. A workaround has been to create Super BOMs. Super BOMs are overloaded representations of a product, typically containing all possible options that can be added. Once the real BOM is to be generated based on the actual order, lines of the Super BOM are removed to represent the actual product to build. However, for more complex products, where the structure is different for each order, this approach is problematic.

A Super BOM includes all possible variants, when the actual BOM is generated, lines are removed to represent the actual product to build

The Super BOM Challenge

One product model, often called a super BOM, typically covers one certain size and type of product. A wide assortment, with different product sizes and types, requires multiple Super BOMs.

Another challenge is to connect two organizational areas that are using different product structures, definitions, and levels of detail: Sales with its typically flat, high-level structure and R&D, engineering, and production with their hierarchical structure and full detail. The super BOM approach works fine for products with a rather low variance and complexity, i.e. where one super BOM is enough. But when variance and product complexity increase, the maintenance cost for multiple super BOM explodes and connecting sales, R&D, engineering, and production systems becomes difficult, expensive, and unstable. If it's doable at all.

What is a Modular BOM?

In contrast to a super BOM, a modular BOM allows you to have a dynamic product model in R&D and engineering that can be connected to sales. The modular BOM separates the actual hierarchy of the product (structure) from the parts and assemblies (content). The structure is dynamic, meaning that branches can be added or removed on-the-fly when the actual BOM to produce is generated during configuration. This enables parts and assemblies to be reused more efficiently and one modular BOM can often describe the complete assortment.

Using a single modular BOM rather than multiple super BOMs has many benefits. Maintaining one structure not only reduces work, but it also improves consistency. Using one structure also simplifies the setup of sales configuration with commercial packaging and pricing.

A modular BOM ensures consistency and synchronization of customer requests with sales, R&D, engineering, and production. It's flexible and connects the organization. For a deeper read please go to Product Masters and BOM structures for Product Configuration.

One-Touch Configuration

One-touch Configuration means that each customer order is handled only once from end-to-end in the sales to delivery information flow. That touch is typically a sales representative or the customer directly through an online self-service configurator.

The product configurator needs to secure that the input is correct, complete, and consistent. When it is, interconnected systems can generate all the required information objects, such as quotes, internal and external specifications, bill of materials, documentation, production and material plans, and production orders.

One-touch configuration, also known as straight-through processing, is very achievable for product-based businesses. The products and their documentation are predefined, and the product configurator has the relatively simple task of filtering out a valid solution from the catalog.

Complex products come in too many combinations for a back-end operation with a predefined product catalog. Complex products tend to involve a unique combination that has never been sold, engineered, nor produced before. Depending on the case, and if the product is configured or customized, different solutions and integrations are needed.

In this blog post, Restructuring the Product Master for One-Touch Product Configuration, you can read more on the fundamental prerequisites to enable one-touch product configuration. And with a real-world example, demonstrate how a product master was restructured to enable implementation.

Guided Selling

Guided selling is a concept to empower the salesperson (or the online product configurator) with expert knowledge on how to ask the relevant questions to the customer. In complex sales, it is a challenge to scale the number of salespersons. It takes a long time to learn all the ins and outs of the different markets, customers, applications, and products. Experienced salespersons become irreplaceable assets since they have all the needed knowledge in their heads.

By documenting:

- The logic of what questions to ask in which order is based on the existing knowledge of the customer

- How to adjust the questions based on previous answers

- How to configure and propose attractive solutions based on the answers

…you can scale the total sales expertise of the company. And you can improve the documented knowledge over time. See this blog for examples of companies who use Product Configurators and the Importance of Guided Selling.

Software for Product Configuration

Software solutions for Product Configuration have been used since the early 1980's. Traditionally there's a division between internal configuration processes, typically handled by engineering, to create BOMs and external configuration processes, typically handled by Sales, with the target of creating and presenting quotes to a potential customer. More on how to successfully implement a CPQ solution. Sales configurators are often called CPQ (Configure-Price-Quote) systems today. Many software solutions can handle both Sales and BOM configuration.

The software solutions also differ in how they setup and solve the configuration models. Because of this some solutions can be preferred for a specific situation, while others might be preferable for other situations.

CPQ – Configure-Price-Quote

CPQ is a term commonly used to describe software solutions for sales configuration. There are three main functions that must be performed – Configuring a solution that fits the need, Pricing the solution to make it attractive and profitable, and generating a Quote that is presented to the customer. The quote would typically describe and detail the suggested solution and price.

There is a multitude of different CPQ software available on the market, many are already integrated into popular CRM solutions to be incorporated into existing sales workflows.

CPQ and visual configuration

Many CPQ solutions also include functionality to visualize the proposed solution, sometimes referred to as visual configuration. Either in pre-rendered images, or in dynamic 3D-models presented on a screen or even in VR and AR.

CPQ solutions may need integrations to CAD in case there is a need to generate a drawing or 3D model to be supplied with the quote.

To achieve true end-to-end configuration, more solutions are needed unless the business is purely product-based with predefined fixed products. These solutions must generate a complete and valid BOM and place the production order.

BOM Configurator

BOM Configurators, sometimes referred to as technical configurators, or product configurators (this article uses the term product configuration to describe all types of configuration), is typically used internally in an engineering (either in the order execution or in product development) context to generate a BOM that is valid. The validity is ensured by controlling that the BOM satisfies the constraints that are given. One example of such a constraint could be that tire A only fits with Wheel A. Or that the tire inner diameter must equal the wheel outer diameter. The output could be saved as a BOM in a PLM or ERP system.

Design Automation

Design automation is a term used for automating adjustments of CAD models based on parameters. This way, the configurator can produce a 3D-model that is representing the actual configuration in addition to the BOM . In some applications, it is a requirement that already the sales process can generate a correct CAD model.

The parameters may be related to some dimension of the design, also known as parametric design and the design automation solution can then alter this parameter and have the CAD solution generate an update model based on the new dimension.

The parameters can also be used to drive a more complex model where different parts are hidden or replaced and positioned to facilitate a more dynamic automatic CAD model.

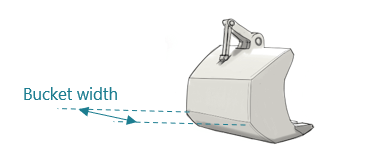

By making the bucket width a parameter, different capacity buckets can be designed automatically with design automation software

Configuration Model Creation

Depending on the nature of the configurator and its solver algorithm, the definition of the rules (configurator model) will be different. Three typical types are sequential, relational, and constraint-based product configurators.

Sequential

Questions are asked in pre-determined sequence. Each answer eliminates choices on the questions that will follow.

The sequential configurator is perhaps the most common type of configurator. The configurator model can be visualised as a tree, where every node is the answer to a question. Practically it is often modelled by entering a series of If-Then statements leading to a predefined combination. It's easy to start and intuitive to create for simple models.

In most cases the sequential configurator enforces a specific order of the questions and that all questions are answered. This can lead to dead ends for the user. Let's say that I want a convertible, but already my first answer about trunk size leads me down a branch without any convertible models. To find the convertible models, I would have to restart the configurator, and try to find the right combinations.

Maintaining the configuration model is hard for complex products, one change in the product may need many changes to the model. A single new option potentially doubles the tree.

Relational

The relational configurator is based on tables that explain what goes with what. It is very intuitive to create and easy to understand. A relational model is created by setting up one or more tables with all compatible and incompatible combinations. One component on the X-axis and the other on the Y-axis. In the intersection of the two axes, information about their compatibility is submitted.

The table grows exponentially for every component added to the configuration. Maintenance will become more and more unmanageable as the tables grow large in size and numbers.

If the compatibility between certain components is changed, those relational tables basically must be re-created. Finally, "Compatible / Not compatible" does not really tell you anything about why the components are compatible or not, so each relational table will contain a mix of:

-

- technical compatibility - if two components fit together technically

- application compatibility - if two components fit together for a certain application or use case

- commercial compatibility - if we for commercial reasons decide to limit the compatibility, for example, to never use the largest wheel diameter on the cheapest brand

Constraint-based

Finally, constraint-based configurators are the most challenging to mentally grasp and getting started with. Long-term though, it is the most powerful and cost-efficient type of configurator for products that have moderate to large number of selections and change rate.

In a constraint-based configurator you specify the attributes of each real or virtual part or component. The configurator solver then secures that all selections are consistent throughout the configured product or solution.

The configurator model should be based on why certain components are compatible and add a constraint matching those attributes. The constraint-based configurator establishes not only if certain components are compatible, but also why they are compatible or not.

3 Main Benefits of Product Configuration

Speed

By using a product configurator, quotes can be generated faster, in some cases instantly in front of the customer. Many companies measure the quote turnaround time, or RFQ response time, and see it is an important factor in winning the deal.

The product configurator will also generate a more precise configuration directly, meaning that the production and purchase orders can be released faster which in turn reduces the overall order-to-delivery time. In the optimal case, the exact configuration is known already when the quote is generated.

Quality

The product configurator structures the know-how needed to transform a need into a solution. This has four major quality-related effects:

- Reduce or remove the person dependency when creating the order, by equipping every salesperson with the same necessary know-how. This ensures that the solutions are scoped and dimensioned correctly and that solutions are proposed in consistent ways according to both customer preferences and internal business criteria.

- Continuous improvement of the structured knowledge is enabled. Over time the model can be perfected, and it will always have the latest information.

- When new products, functions, features, or performance levels are introduced they can be simultaneously and instantly available to the entire sales force.

- For complex products, the configurator solver can evaluate far more possible solutions than a sales engineer. The solutions can be chosen closer to the needed specification, optimizing cost and performance.

Cost

A product configurator can save cost in two ways:

- Manhours for salespersons and sales engineers by automation of sales and order handling activities.

- Optimal solutions for the given need. By not over-specifying the product " just to be sure", the production cost can be minimized while keeping the required performance.

Product Configuration is the Foundation for Mass Customization

A unified modular and configurable product platform is optimal for mass customization in configuration- and project-based businesses. Whether you're aiming for CPQ sales configuration, BOM configuration, or end-to-end configuration in a one-touch flow; it is the only way to allow for true configurability without an explosion of the internal complexity in the organization.

The term mass customization was coined around the millennial shift, and since then it has become even more important to succeed in the marketplace. The existence of product configurators in the industrial IT system has turned into a fact.

However, as I have explained in this article, excelling in Product Configuration is not only a matter of selecting and implementing a software tool. To do it in an efficient and sustainable way, the product must be modular, and the supply chain and sales processes must be aligned with the capabilities of the product platform. Leaders in the field have analyzed the need for information along the order-to-delivery process to optimize the setups of product structures in the different IT systems, minimizing the need of super BOMS, and structure transformations, for a true one-touch configuration.

Talk to us about Product Configuration!

Over the past decades, we have focused 100% on helping businesses worldwide improve their product configuration and configurability.

We are always interested to hear your story and discuss how you can improve from where you are, let us be your sounding board reach out to me today.