Learn how Wärtsilä achieved:

-

45% shorter time to market

-

43% less part numbers

-

50% reduced assembly lead time

Mabe has built a faster, more agile, and more resilient operation, designed to grow without adding complexity

As a global leader in home appliances, Mabe faced mounting pressure to respond faster to market demands while managing a vast and growing product portfolio. The solution wasn’t more people—it was less complexity and more composability. With support from Modular Management, Mabe restructured its operations around a modular product architecture, powered by PALMA®. This shift enabled configuration-driven product development, streamlined planning and release, of products and a business model ready to scale without added cost or chaos.

Reduction in product data setup effort

Like many competitors, Mabe had reached the point where product complexity was no longer manageable, it was slowing the business down. Older products from acquisitions, overlapping platforms, and region-specific designs created an ever-expanding SKU count. Cost-cutting efforts often added variation without simplifying the portfolio.

One example: the cooking appliance factory in San Luis Potosí, Mexico, Mabe’s most complex site, produced 2.8 million units annually across 654 SKUs. Each month, 43 SKUs were added and 41 removed, yet only 82% were actively produced. The churn strained people, systems, and processes, and similar patterns emerged across other sites and categories.

Meanwhile, market expectations were rising. Speed to market and responsiveness were critical, but adding staff wasn’t viable in a mature, cost-focused industry. The real need: reduce complexity at the source and establish a structured, scalable portfolio.

Thousands of SKUs across regions, many overlapping or redundant

Legacy products and platforms retained without consolidation

High-volume and low-volume production competing for the same resources

Constant SKU churn creating operational instability

Manual tools (spreadsheets, slides) slowing decision-making

Growing market pressure for faster launches and tailored products

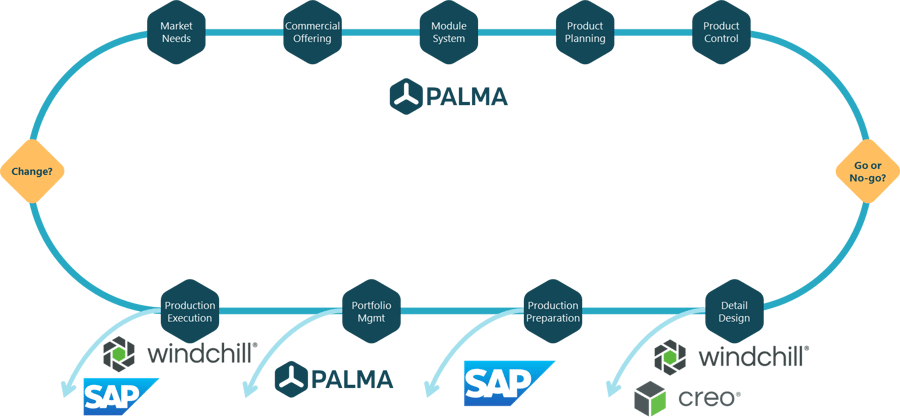

To transform its operations, Mabe needed more than a new process—it needed a digital foundation. That’s where PALMA, developed by Modular Management, became the cornerstone of change. We helped Mabe implement a configuration-driven product architecture and connect it end-to-end across PLM, ERP, and CAD systems.

Integrated product lifecycle loop, PALMA connects market needs to modular architecture, planning, and execution with

With PALMA, Mabe moved from manual SKU creation to configuration-based planning using predefined module variants. This centralized product model eliminated redundant work, automated country- and brand-specific logic, and ensured consistent, error-free product definitions across teams.

Integration was key: PALMA unified data flows from product planning to engineering and manufacturing, cutting lead times and enabling real-time decisions. The platform’s Product Specification Matrix became the single source of truth—empowering teams to audit, update, and scale with confidence.

What began as a solution for cooking appliances evolved into a company-wide transformation. Today, configuration-based thinking and PALMA are embedded in how Mabe designs, develops, and delivers products across its entire white goods portfolio.

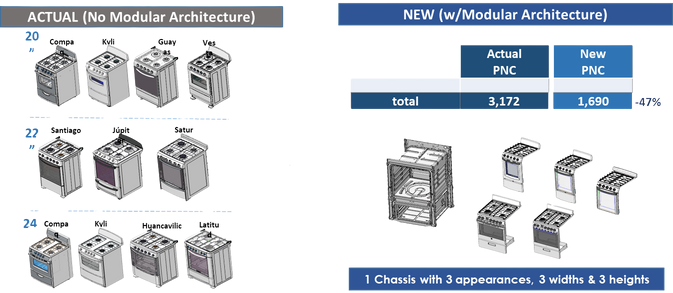

Transition from a non-modular product lineup to a streamlined modular architecture

Mabe transitioned from SKU-by-SKU development to a modular configuration model. New SKUs are now assembled from pre-approved modules with built-in country and brand logic. PALMA allows teams to audit SKUs, control variants, and manage lifecycle changes across the portfolio. Lead times fell dramatically, rework dropped, and product planning was unified across Mabe, GE Appliances, and Haier. The transformation has scaled to the majority of Mabe's portfolio, with full leadership endorsement.

Product Planning: Unified across Mabe, GE Appliances, and Haier; SKUs validated instantly against existing modules; configuration rules remove guesswork and ensure accuracy.

Top-Down Design: Engineers work from a global product structure, reusing module variants first; PALMA–Windchill integration automatically generates correct product structures.

Cost Management: Module-based cost data reused portfolio-wide; costing time for new SKUs cut by 80%; cost decisions accurate from the start.

Operational Agility: SKU lead time reduced from one month to one day; setup effort cut by 90%; maintenance workload down 80%; country-specific requirements applied automatically.

Change Management: Instant visibility into part usage and affected SKUs when suppliers, components, or features change; smarter sourcing and production decisions enabled.

"With PALMA, we don’t just launch products faster, we make smarter decisions from day one. It’s clarity, control, and confidence in one platform”.

María Mata

Modular Architecture Leader | Mabe

Mabe’s transformation shows what’s possible when configuration becomes the foundation of product development. By adopting a configuration-driven approach built on modular product architecture, Mabe replaced manual processes with digital precision—making it faster, easier, and more cost-effective to deliver the right products to every market.

This shift wasn’t just about improving operations—it enabled Mabe to grow with confidence. Configuration gave teams the flexibility to respond quickly to changes, scale efficiently across brands and geographies, and maintain consistency without compromising speed or innovation.

For manufacturers facing the pressures of global scale and constant change, Mabe’s success offers a clear path forward: embed configurability, streamline with digital integration, and build a business that’s ready to evolve.

45% shorter time to market

43% less part numbers

50% reduced assembly lead time

40% less part numbers

25% shorter time to market

1+ billion in added shareholder value

50% reduced design cost

25% faster construction time

50% less on-site indirect cost