Learn how Wärtsilä achieved:

-

45% shorter time to market

-

43% less part numbers

-

50% reduced assembly lead time

Mabe has built a faster, more agile, and more resilient operation, designed to grow without adding complexity

As a global leader in home appliances, Mabe faced mounting pressure to respond faster to market demands while managing a vast and growing product portfolio. The solution wasn’t more people—it was less complexity and more composability. With support from Modular Management, Mabe restructured its operations around a modular product architecture, powered by PALMA®. This shift enabled configuration-driven product development, streamlined planning and release, of products and a business model ready to scale without added cost or chaos.

Mabe’s success had introduced its biggest challenge: complexity. Across eight production sites, thousands of SKUs spanned brands, countries, and customer preferences. With acquisitions, overlapping platforms, and ad hoc product launches, Mabe’s operations were slowing down. For example, one factory managed 654 SKUs, introducing and phasing out 40+ every month.

Manual processes couldn’t keep up. Teams were relying on Excel and disconnected systems, and factories were split between high-volume efficiency and low-volume flexibility—all in the same space. Adding people wasn’t the answer. What Mabe needed was a new architecture: one that allowed variety, but only where it added value.

Older products that came with acquisitions

New platforms added without removing the old ones

Designs created for specific regions or brands.

At the same time, market expectations were changing. Mabe faced pressure to:

Mabe’s transformation began with a bold question: What if we could grow and offer more variety—without making everything more complicated?

Working closely with Modular Management, Mabe embraced a long-term shift from traditional, SKU-based development to a modular product architecture. Together, the teams restructured product categories to be built from standardized modules—each with a defined purpose, limited variants, and reusable interfaces. This allowed Mabe to generate wide product variety from a controlled, rationalized architecture.

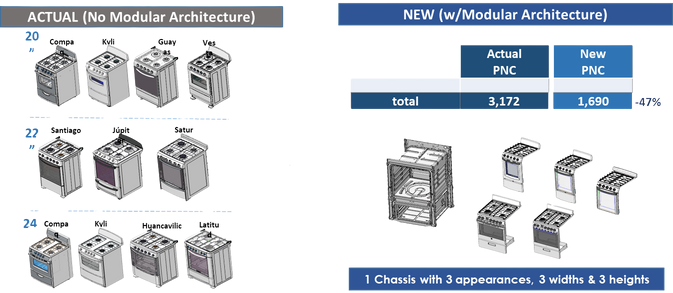

The transformation started with the most complex category: free-standing cooking appliances. Rather than redesigning one SKU at a time, Mabe tackled the entire platform as a configurable system. Modules were selected based on customer value, operational efficiency, and long-term adaptability. The strategy expanded into other product lines—washing machines, exhaust hoods, refrigerators, water heaters—applying the same principles to scale modularity across the business.

Transition from a non-modular product lineup to a streamlined modular architecture

The results were measurable—and replicable. For example, Mabe’s largest cooking factory was able to consolidate 27 production lines into fewer, more efficient setups by standardizing how products were assembled. Configuration rules replaced one-off engineering. Manual work dropped significantly.

Most importantly, this was not a one-off project. Modular Management helped Mabe embed modular thinking into its product development DNA. Today, every new platform starts with modular product architecture—a repeatable system that balances customization with control.

Want to learn how Mabe extended this transformation with digital configuration?

Explore the Mabe PALMA case story →

From 2015 to 2025, Mabe doubled its revenue—not by adding complexity, but by eliminating it. By standardizing variation and embedding configuration into the product lifecycle, the company created a flexible, scalable product system.

The success of Mabe’s transformation wasn’t just in the numbers—it was in the way work got done across the business. Here’s how modular architecture and configuration-based development improved core processes:

Product Planning:

With PALMA at the center, Mabe treats every SKU as a configuration of reusable module variants. The system instantly checks if a new SKU can be built from existing modules and enforces rules for country, brand, and performance, reducing errors and guesswork. Today, product planning is consolidated across Mabe, GE Appliances, and Haier for visibility, consistency, and speed.

Top-Down Design:

Cost Management:

SKU lead time reduced from 1 month to 1 day

90% reduction in product data setup effort

80% less effort required for product maintenance

47% reduction of overall count of unique part numbers

63% reduction in stamping tools

"With PALMA, we don’t just launch products faster, we make smarter decisions from day one. It’s clarity, control, and confidence in one platform”.

María Mata

Modular Architecture Leader | Mabe

Mabe’s journey shows what’s possible when configurability becomes the foundation of product strategy. By rethinking its product architecture and implementing a digital model with PALMA®, Mabe created a smarter, leaner, and faster operation.

This approach didn’t just improve operations—it gave Mabe the capability to grow without adding cost, risk, or overhead. For any manufacturer facing the limits of scale and SKU sprawl, Mabe’s transformation offers a clear lesson:

Strategic configurability is how product variety becomes a strength—not a burden.

45% shorter time to market

43% less part numbers

50% reduced assembly lead time

40% less part numbers

25% shorter time to market

1+ billion in added shareholder value

50% reduced design cost

25% faster construction time

50% less on-site indirect cost