Expand Market Growth with Complexity at Check

Inspiration for Hardware Design

Case story

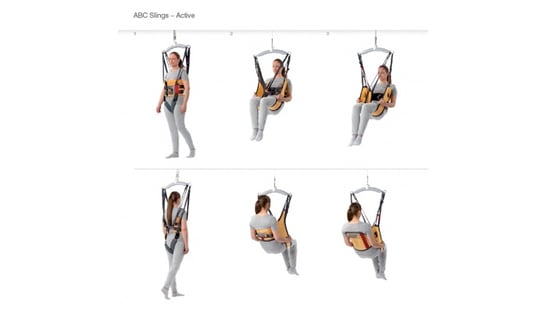

Guldman People Lifting Systems

In 2003, Guldmann was the market leader for ceiling and mobile lifts. Sales in this market were strong and they were contributing a significant portion of the bottom-line. CEO, Carsten Guldmann, however, was concerned about the challenges that the company would face as it continued to grow. He and the team of top managers also recognized the opportunity in the market would be with continued product diversification and customization. Users and buyers of lifts were looking for more customized products.

With their eye on the long-term success of the company, the leaders of the company looked for a way to grow the company without becoming over burdened by the complexity of increased size. They also looked for a way to provide an increasingly wide range of products while maintaining the cost, quality and lead-time of the solutions to customers.

Summary

Guldmann People Lifting Systems were looking to scale up a diversified product portfolio. The market was demanding a larger range of ceiling-mounted and mobile people lifts at acceptable delivery and price points. The challenge was to keep growing while maintaining market position as a state-of-the-art, customer-focused lift supplier; without losing control over cost.

The company was also looking to grow in developing countries, where they needed to extend their product offering with lower cost variants. To enable this, Guldmann implemented a modularity program.

The program delivered dramatic cost-side results including:

90% reduction in part numbers per product and level of inventory;decrease in product lead time;

significant cost reductions;

higher volume sourcing.

On the revenue side, annual revenues were estimated to have doubled.

Full Story

Business Situation

In 2003, Guldmann was the market leader for ceiling and mobile lifts. Sales in this market were strong and they were contributing a significant portion of the bottom-line. CEO, Carsten Guldmann, however, was concerned about the challenges that the company would face as it continued to grow. He and the team of top managers also recognized the opportunity in the market would be with continued product diversification and customization. Users and buyers of lifts were looking for more customized products.

With their eye on the long-term success of the company, the leaders of the company looked for a way to grow the company without becoming over burdened by the complexity of increased size. They also looked for a way to provide an increasingly wide range of products while maintaining the cost, quality and lead-time of the solutions to customers.

Product Marketing & Management

The team identified that the GH2 Platform of lifting products would be challenged to address the changing market needs with the right price-points and lead times. The company had strong capabilities to deliver customized solutions for any one customer, but they had limited capacity and a limited set of customers that would wait for engineer-to-order systems.

The company needed to predict more of the range of solutions that were needed in the market and spend the time to develop products ahead of actual orders. Of course, there would always be special needs within many of their delivered solutions, but they were striving for a major portion of solutions to be delivered from pre-developed components.

Product Design & Engineering

The GH2 Platform comprised a flexible assortment of products, but it was clear that the current design would lead to larger and larger levels of overhead to manage the added models that the market requested. The ceiling lifts are complex medical-grade systems with stressed and moving components. Careful and intricate engineered efforts are required to ensure robust and long-term operation.

There was no established product development process at Guldmann to introduce new designs. The product platform had evolved over time with new customer projects. The replacement of the GH2 platform would be a major undertaking for the company, one that had never been done before.

Product Operations

Sourcing and manufacturing at Guldmann had been deployed mostly on an individual project basis. There were some common components that could be manufactured in volume and made available in inventory, but the majority of components were built from design drawings that were recently created.

Goals for the Modular Architecture

Guldmann sought to create a new product platform that would sustain them for the next twenty years. They intended to keep growing while maintaining a market position of a state-of-the-art, customer-focused supplier without losing control over the cost. They also looked to grow in the developing regions of the world where they also needed to extend their product offering with lower cost variants.

The new platform would be based on a Modular Product Architecture from which a steady stream of product variants could be drawn over its lifetime. The plan was to make a major upfront investment to develop and ensure a robust and beneficial platform. They would then leverage the investment by accelerating the launch of many new module variants. This was the largest product development project the company had every attempted.

Revenue Growth

By offering an expanded range of price points and customizable configurations, Guldmann planned for large sales growth within new channels and geographic locations. In a market where the other major competitors were offering mostly standardized solutions, they expected to win with solutions matched better to the specific customer needs. It was not a technical challenge in designing product that could do the job of lifting people; it was a challenge to deliver products in an acceptable amount of time and at a reasonable price.

Profitability Improvement

By controlling the direct and indirect product costs, the desired price could be supported. Direct material cost would be reduced by purchasing in larger volumes and in fewer transactions. They also sought to eliminate over-specification of components which was a common time-saving practice of selecting components with assured performance versus exactly matching the component to the application.

Indirect cost would be saved in large part due to the reduction in the number of different product designs being managed by the engineering and operations teams. This was indicated by measuring the number of active part numbers. They goal was to cut in half the number of part numbers in the GH2 platform. The company expected to reduce their overall indirect product cost which would come in part from a reduction in materials inventory, work-in-progress and finished goods. They would be working from a master manufacturing plan with greatly reduced lead times.

Modular Architecture in Action

The team at Guldmann developed a Common Unit and Carry Over module called the Chassis Module. A number of other modules with high levels of variance connected to this module via standardized attachment and transfer interfaces.

It is rare that you can connect so many high variance modules to a single Common Unit and Carry Over module.

The Chassis Module was a die-casted aluminum component that integrated a lot of different parts into one. It was the heart of the lift and was planned to remain the same for the 20-year life of the product platform. It can be built in large quantities, and the team worked hard to optimize cost and supply-chain efficiency.

Business Results

In 2007, four years after the work was started, the GH3 platform was launched. By 2012, Guldmann’s annual revenue had doubled and the assortment of products on the new GH3 platform had increased dramatically.

The management team devoted a limited number of resources to the development of the new platform in order to control expenses and keep up sales and delivery of products from the existing platform. This proved to be the right balance of time and investment for the very proactive move Guldmann was making in the market.

After the initial platform launch, the remaining product variants were launched in the next two and half years. They have also continued to launch a new variant each year since. All of this has occurred without the addition of any new research and development resources.

Product Marketing & Management

As of 2012, 70% of the volume had converted over to the new, modular assortment. And by 2013, Guldmann planned to fully phase-out the GH2 product platform.

Their cadence of adding new products looked to continue and they were able to enter the lower end of the market with a limited number of modifications in selected modules.

Guldmann also changed their messaging to the market. They launched a campaign around the central idea of More Time. With products from the GH3 platform, customers were becoming more efficient in their efforts to moving and handling people leaving more time for direct care. The identification of the importance of this benefit to customers came during the process of creating the Modular Product Architecture. Early in the process they used Quality Function Deployment (QFD) to determine the key Customer Values and established that every decision they made about the product could be linked back to the customer. The list of Customer Values became known as the company’s Ten Directives and a poster of QFD was hung in Carsten Guldmann’s office.

Product Development Engineering

Guldmann has started to follow a stage-gate product development process that has given them the discipline to focus their efforts on specific modules to launch pieces of the product assortment in waves. They have done this with a relatively small team while keeping the old platform viable in the market.

The team was diligent in the refinement and perfection of the module system enabling specific strategies for each module and protecting these strategies with robust interfaces. See an illustration of the GH3 module system in Figure 3. Their careful efforts won’t need to be repeated for over twenty years. They are now able to efficiently develop new product variants by making changes to very specific modules and have successfully launched new products every year.

The product development team was also able to simultaneously reduce the total number of active part numbers while increasing the size of the product assortment. The average number of unique part numbers per product variant has been reduced by a factor of ten. With the larger assortment, they are spending less time designing individual customer orders and can focus on new product development or high-value custom lifting systems.

Product Operations

Guldmann created a new assembly line that included module production cells that feed into the final assembly. It was a Kanban system that draws on whole module variants that are then assembled quickly into a final product. They could manage the supply chain for each of the modules and differentiate into the range of final products very late in the process.

Late differentiation was also possible due to the software that was loaded directly on the assembly line for each product variant, including a unique self-test. This enabled quick and easy testing, no matter which product variant was being assembled.

Guldmann also implemented a number of Common Unit modules for efficiency improvements in production and procurement. These modules had only one variant and were included in most lifting products. The supply chain could then be forecasted with greater accurately, with some modules able to be sourced in low-cost countries.