Executive Summary

Engineer to Order (ETO) often feels like the most efficient way to customize your product in markets where it seems that no two customers have the same needs. In reality, it is one of the most expensive operating models in industrial manufacturing.

ETO forces engineering teams to redesign and revalidate solutions order by order. Testing is needed, manufacturing batches stay small, parts multiply, and complexity grows quietly but relentlessly. Over time, cost creeps into every corner of the organization.

Across electrical infrastructure manufacturers we work with, ETO typically drives up to 30 percent higher total costs across engineering, testing, manufacturing, and inventory.

In practice, the cost impact is consistent across manufacturers:

- 20–30 percent higher engineering costs from extra design and validation work

- 30–40 percent higher testing costs due to duplicated certification efforts

- 25–50 percent higher manufacturing costs caused by frequent changeovers and low volumes

- 30–40 percent higher inventory costs driven by poor part reuse

More damaging than the cost itself is the trajectory. Each new order introduces new parts, new variants, and new exceptions. Complexity compounds year after year, quietly inflating the cost base even when revenue grows.

The good news? There is a way out.

Manufacturers that transition from a predominantly ETO model to a Configure to Order (CTO) model, built on a modular and configurable product architecture, retain customer flexibility while significantly reducing cost, lead time, and operational friction.

This blog explains why ETO becomes a operational liability, why many companies misunderstand modularity, and how CTO changes the economics of customization. It also includes a real example of how CommScope moved from customer-unique engineering to CTO, enabling far more product variety with far less complexity.

The Hidden Cost of Engineer to Order in Electrical Infrastructure

For many manufacturers, ETO has been the default way of working for decades. Customers ask for tailored solutions, and ETO delivers exactly that. The problem lies in how those solutions are created.

In an ETO environment, every order triggers engineering changes, new or modified parts, additional documentation, and production adjustments. Testing is repeated, manufacturing runs remain short, parts proliferate, and complexity grows steadily and predictably.

Individually, these steps seem manageable. Collectively, they create a complexity treadmill. The outcome is predictable:

- Engineering capacity is consumed by variation rather than innovation

- Testing and certification repeat work that adds no customer value

- Manufacturing efficiency drops as volumes fragment

ETO does not stabilize. It accumulates complexity by design.

Why ETO Keeps Costs Rising and Why Companies Stay with It

The most expensive aspect of ETO is not the engineering hours tied to a single order. It is the way ETO locks the business into a self-reinforcing complexity cycle.

Every new customer requirement introduces additional components, sourcing dependencies, and production constraints. As a result, growth demands proportional increases in engineering, planning, and operational effort, making scale increasingly difficult.

Despite this, many companies remain committed to ETO. In our experience, three reasons dominate.

First, the cost of complexity is rarely measured or owned. Engineering hours, material cost, and inventory value appear on dashboards. Complexity does not. When the cost of variation is invisible, it is easy to ignore.

Second, ETO can appear profitable in growing markets. As demand increases, companies hire more engineers and planners. The breaking point only becomes visible when talent can no longer be added fast enough to keep pace.

Third, many organizations believe they are already modular.

So You Think You’re Already Modular?Most ETO manufacturers can point to subsystems and call them modules. That is not wrong, but it is incomplete. It is not deep enough into the product architecture. Breaking products into large engineering subsystems helps distribute work across teams for more efficient ETO project management, but that alone does not enable configuration of customer solutions at scale. A strategic modular and configurable product architecture does three things differently:

Most importantly for the business, a high level of reuse at the module level creates economies of scale, allowing variety to grow without a corresponding increase in internal complexity So if engineering is still redesigning parts for most orders, modularity has not been driven deep enough into the product architecture. |

How Configure to Order Changes the Economics of Customization

The shift from ETO to CTO is simple but profound. Variation is handled through configuration, not engineering.

In a CTO model, products are built from pre-validated modules with defined interfaces and rules. Engineering focuses on maintaining and evolving the platform rather than fulfilling individual orders.

This fundamentally changes the cost structure of the business. Common parts replace one-off designs, testing and certification are reused, manufacturing benefits from stable setups and predictable volumes, and manual bill-of-material creation gives way to configuration logic.

Table 1 compares ETO and CTO across design engineering, testing and verification, procurement, inventory, and manufacturing. CTO consistently outperforms ETO by shifting effort upstream into the product architecture, where it scales.

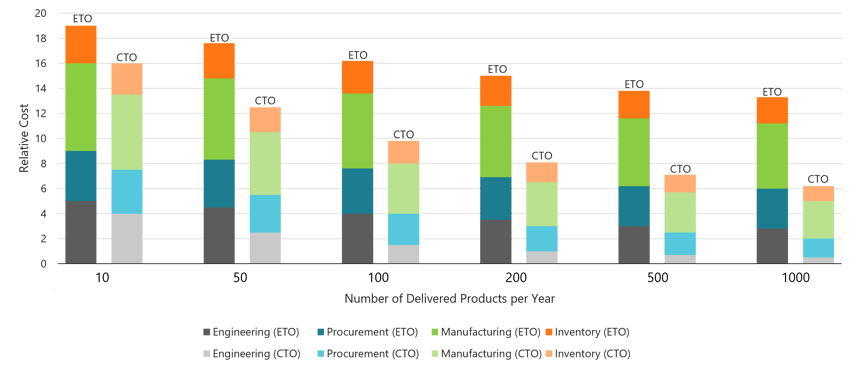

Figure 1 illustrates how cost per delivered product decreases as volume increases under CTO. As reuse increases, engineering, testing, procurement, inventory, and manufacturing costs flatten or decline by 50 percent in design engineering, 40 percent in testing and verification, 30 percent in procurement, 40 percent in inventory, and 25 percent in manufacturing.

The takeaway is clear. CTO does not reduce flexibility. It removes unnecessary work.

Case Story: How CommScope Scaled Variety Without Scaling Complexity

As fiber networks expanded, CommScope faced a classic Engineer to Order challenge. Customer requirements multiplied, deployment scenarios became more diverse, and product variation grew rapidly. What began as flexibility increasingly showed up as longer lead times, rising complexity, and mounting internal cost.

Rather than continuing to engineer customer-unique solutions order by order, CommScope chose a different approach. The objective was not to standardize and limit their product offering. It was to offer more choice to the market while simplifying how products were designed, built, and delivered.

CommScope transitioned toward a CTO model enabled by a modular product architecture. Repeated engineering work was replaced with predefined building blocks and configuration rules. Variation was designed into the platform instead of added after the fact.

The result was a product platform that could scale variety without scaling effort.

Results at a glance• 50x more product configurations • 75% fewer components • 50% faster new product development • Order turnaround reduced from days to hours

|

Figure 2: CommScope NOVUX™ platform

CommScope significantly expanded customer choice while reducing internal complexity. That is what CTO looks like when modularity is applied strategically.

Why Configure to Order Is the Operating Model for Scalable Growth

ETO accumulates complexity. CTO contains it.

Manufacturers that continue to rely on ETO will inevitably face rising costs, longer lead times, and constrained growth as product variety increases. CTO, enabled by a modular and configurable product architecture, changes that trajectory.

With CTO, manufacturers reduce engineering effort by reusing validated modules, eliminate repeated testing and compliance work, stabilize manufacturing operations, consolidate procurement and inventory, and respond faster to customers without redesign.

CTO starts with product architecture. Everything else follows.

Next Steps

If this resonates, here are three practical ways to go deeper:

- Download the Manufacturer’s Guide: From Engineer to Order to Configure to Order

A practical guide explaining when ETO becomes a liability, what CTO changes, and how manufacturers transition without disrupting the business. - Assess Your Product Complexity with the Complexity Scorecard

A short, structured assessment to quantify how complexity shows up in your product portfolio, engineering effort, and operations. - Download the Practical Roadmap to Product Modularity

A step-by-step roadmap showing how to move from today’s product structure toward a modular, configurable architecture that supports CTO.

If your product portfolio is growing faster than your margins, the problem is not market demand.

It is complexity.