Learn how Wärtsilä achieved:

-

45% shorter time to market

-

43% less part numbers

-

50% reduced assembly lead time

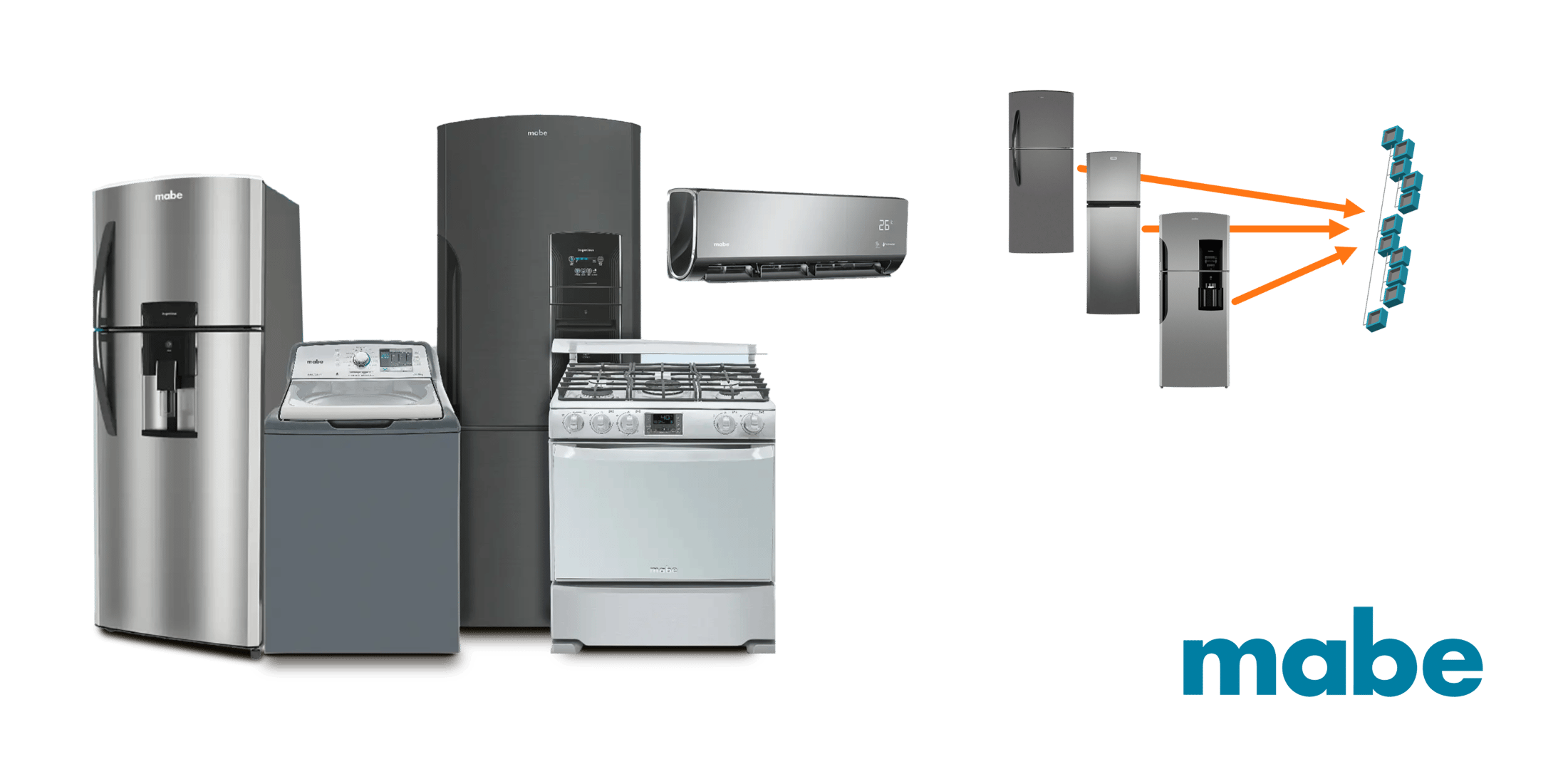

Founded in 1946 and headquartered in Mexico City, Mabe has grown into one of the world’s leading manufacturers of home appliances, producing everything from cooking and refrigeration to laundry, water heating,and air conditioning products. With over ten production sites across Latin America, an R&D center in Querétaro, and a team of around 20,000 employees, Mabe serves customers in more than 80 countries.

As the market leader in Latin America, Mabe built its success on a wide product range, regional flexibility, and smart growth, both through innovation and acquisitions. But in a mature and consolidated industry, scale often brings added challenges. To supply worldclass appliances that fulfill customer needs along with safety, nice appearance, cost and quality, home appliance companies like Mabe must constantly evolve.

What once set Mabe apart, its ability to customize quickly and serve many different markets, was now becoming difficult to manage. With thousands of SKUs across legacy brands and global regions, Mabe’s portfolio had become increasingly complex. Overlapping products, outdated platforms, and a relentless pace of change made it harder to move quickly and efficiently. The variety that once powered their growth was now putting pressure on operations, making it difficult to scale effectively.

Reduction in product data setup effort

Cut in Maintenance Workload

Faster time to release the BOM for a new

SKU

Like many of its competitors, Mabe had reached the point where product complexity was no longer something they could work around, it had started to slow the business down. The reasons were many and familiar to other manufacturers

Efforts to cut costs and improve quality added more variation, with parts made for specific SKUs or changes that only applied to high-volume models, without simplifying the rest of the portfolio.

One of the clearest examples was Mabe’s cooking appliance factory in San Luis Potosí, Mexico — the company’s most complex site. Producing millions of units annually, the factory managed an extensive portfolio of SKUs. Each month, many new SKUs were added and fewer were phased out, creating constant churn and a steady increase in complexity. Many valuable resources were consumed in the planning, design, and maintenance of these SKUs.

And this wasn’t an isolated case. The same story played out in other factories and product categories. With thousands of SKUs to manage, nearly every production site had become large and difficult to operate. High-volume products needed fast, streamlined production lines. Lowvolume products required flexible setups. These very different ways of working had to share the same space and equipment, creating daily trade-offs and making the entire operation harder to control.

At the same time, market expectations were changing. Mabe faced pressure to:

But hiring more people wasn’t a realistic solution. The industry was mature and cost-focused, and it was difficult to find the right talent. Adding staff wouldn’t solve the bigger issue anyway, Mabe needed to reduce complexity at the source, not just manage around it. What they needed was a new way to structure their product portfolio, one that could bring order, speed, and clarity to an increasingly complicated business.

But hiring more people wasn’t a realistic solution. The industry was mature and cost-focused, and it was difficult to find the right talent. Adding staff wouldn’t solve the bigger issue anyway, Mabe needed to reduce complexity at the source, not just manage around it. What they needed was a new way to structure their product portfolio, one that could bring order, speed, and clarity to an increasingly complicated business. The academic world sparked interest, but Mabe quickly realized there was no off-the-shelf methodology from academia that could be applied directly to their business.

That changed when they connected with Modular Management, a company with decades of experience helping global manufacturers implement modular product architecture at scale. The approach immediately resonated with Mabe’s goals: simplify operations, improve responsiveness, and stop the cycle of unnecessary complexity that had built up over years of isolated product launches.

The team at Mabe recognized that while some complexity was necessary, to serve different countries, brands, and retail channels, much of it wasn’t adding value for customers. The pressure to quickly introduce new SKUs had led to a fragmented product landscape, where new parts and platforms were layered on top of existing ones without stepping back to streamline or consolidate. Mabe set out to break this cycle and build a structure that would support faster time-to-market, leaner factories, and a stronger foundation for long-term growth.

Image 1. Lineup of residential kitchen appliances, including refrigerators and gas/electric ranges by Mabe.

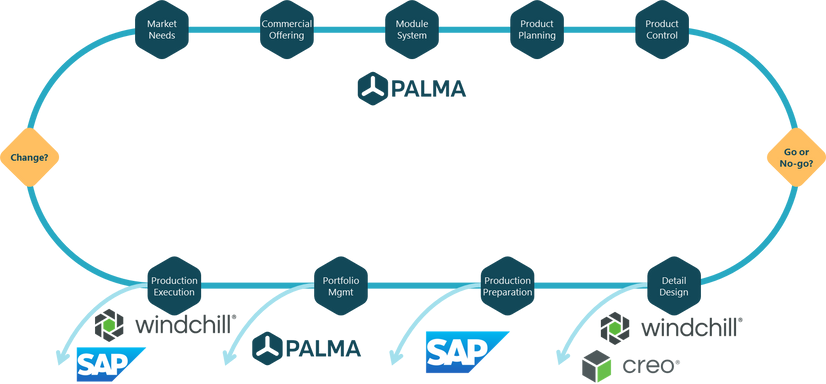

Modular product architecture became the core of this strategy. It offered a way to define standardized building blocks—or modules—that could be shared across current and future products. Each module would have a clear purpose, a controlled number of variants, and guidelines for when new ones should be introduced. With shared modules and standardized interfaces, Mabe’s engineering and manufacturing teams could move away from designing every product from scratch to instead building from a common foundation.

This structure is accompanied by digitalization and connection of product information all the way from product planning, through design and manufacturing. Mabe wanted many fewer human touches of the information that add lead time and opportunities for errors. With the centralized set of building blocks and all-powerful standardized interfaces, manufacturing could have the opportunity to consolidate assembly lines and better optimize their space.

The Mabe team needed to improve the consistency of production and supply chain in the factory, decrease time to market for new products while driving growth and improving product development efficiency. They wanted a lean and flexible supply chain and a platform for supply chain optimization. One that could respond more efficiently (quality, time and investment cost)

to customer needs. Analysis revealed that only half as many lines were needed to reach optimal productivity, if complexity could be reduced. Underpinning all of this was a shift in mindset. As one company leader put it:

"It is a mindset… begins and ends with the customers."

Mabe’s transformation wasn’t just about technical change, it was about focusing only on the complexity that mattered to customers, and letting go of everything else.

With Modular Management as their guide, Mabe set down the path to create modular product architectures for each of their product categories. They started with free-standing ranges in the smaller sizes that are mostly sold in Latin American countries. They worked on the whole family of products at the same time, choosing modules with the appropriate strategies and designing standardized interfaces that could also be used for future products. By identifying many “operational excellence” modules that did not need to vary for customer reasons, they reduced the overall count of unique part numbers by 47%. This was done while growing the overall number of SKUs. At the same time, they also reduced the number of stamping tools by 63%.

The modular product architecture was implemented into Mabe’s product information and design systems, enabling a new way of working and the means to leverage the reduced complexity. They were able to automate the process from portfolio planning to engineering BOM creation in Windchill PLM all the way to manufacturing BOM and routing in SAP. They could now work on a whole family of products at the same time, instead of one-by-one.

The modular product architecture was implemented into Mabe’s product information and design systems, enabling a new way of working and the means to leverage the reduced complexity. They were able to automate the process from portfolio planning to engineering BOM creation in Windchill PLM all the way to manufacturing BOM and routing in SAP. They could now work on a whole family of products at the same time, instead of one-by-one.

Figure 1. Integrated product lifecycle loop, PALMA connects market needs to modular architecture, planning, and execution with smooth collaboration across Windchill, SAP, and Creo.

Mabe has continued, with varying levels of guidance from Modular Management, down the path for the rest of their product categories, including larger ranges, exhaust hoods, washing machines, refrigerators, freezers and water heaters. Today, they are doing it all on their own. All of these are being managed through a modular product architecture that originates in Modular Management’s PALMA software. Mabe did all of this with remarkable speed, turning over all of thier cooking platfroms in seven years. They have also embedded the methodology into their way of working. Now, all new programs start with modular product architecture.

By shifting to a modular product architecture and digitally connection core product and design processes, Mabe fundamentally changed the way it brings products to market. Mabe became more competitive and significantly increased its revenue by adding more choice to the market without adding complexity.

Product Planning:

With PALMA at the center of its planning process, Mabe treats every SKU as a specific configuration of reusable module variants. When a new SKU is proposed, the team can instantly

check whether it can be built from existing modules. If new modules are required, PALMA automatically identifies the gap. The configurator ensures that the right variants are selected based on product plans, enforcing rules tied to country, brand, and performance levels, removing guesswork and reducing manual errors. Today, Mabe consolidates product planning across Mabe, in one system, ensuring visibility, consistency, and faster execution.

Top-Down Design:

Mabe’s design process now starts with a global product structure. Engineers build every new SKU using existing module variants first, creating new parts only when needed. This top-down approach reduces errors and ensures design consistency. Through PALMA’s integration with Windchill, the correct product structure is generated automatically for each configuration, eliminating the need for manual input and reducing reliance on individual judgment or memory.

Cost Management:

Cost efficiency has also improved through smart reuse. Costing data from existing module variants is reused in every new SKU where applicable, enabling quick, portfolio-wide updates when pricesor suppliers change. The time needed for costing new SKUs has dropped by 80%. The configurator ensures that cost-relevant decisions are accurate from the start, reducing both overhead and the risk of financial surprises later in the process.

New Product or Supplier Start-Up:

Before a new SKU reaches the production floor, teams can now audit the parts used in each module variant to avoid downstream issues. When a change occurs, such as a new supplier, a part improvement, or a component becoming obsolete, Mabe immediately knows which SKUs and factories are affected. This visibility allows them to implement changes quickly and consistently. The ability to see how each part is used across all SKUs, along with associated volumes, enables smarter sourcing and production decisions.

"With PALMA, we don’t just launch products faster, we make smarter decisions from day one. It’s clarity, control, and confidence in one platform”.

M.Mata

Modular Architecture Leader | Mabe

The impact of this transformation is measurable. Time to release the bill of materials for a new SKU has dropped from one month to one day. The resources needed to manage product data for new introductions have been reduced by 90% and for maintenance by 80%. Errors and rework have dropped significantly, and country-specific product requirements are applied automatically. With PALMA and modular product architecture, Mabe has built a faster, more agile, and more resilient operation, designed to grow without adding complexity.

45% shorter time to market

43% less part numbers

50% reduced assembly lead time

40% less part numbers

25% shorter time to market

1+ billion in added shareholder value

50% reduced design cost

25% faster construction time

50% less on-site indirect cost