Learn how Commscope achieved:

-

75% less part numbers

-

50x market offerings

-

Quotation lead time reduced from 7 Days to 1

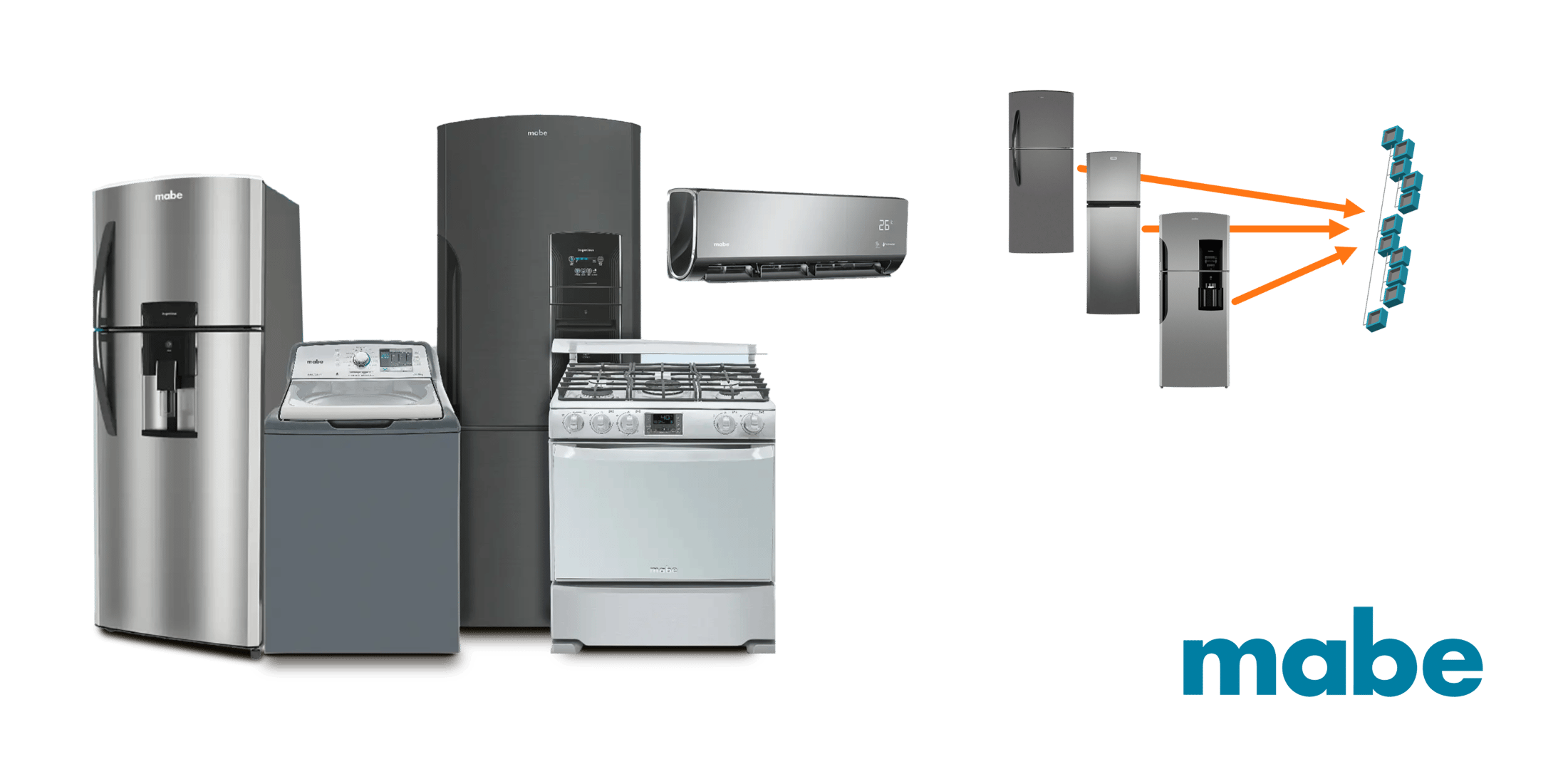

Founded in 1946 and headquartered in Mexico City, Mabe has grown into one of the world’s leading manufacturers of home appliances, producing everything from cooking and refrigeration to laundry, water heating, and air conditioning products. With over ten production sites across Latin America, an R&D center in Querétaro, and a team of around 20,000 employees, Mabe serves customers in more than 80 countries.

To supply worldclass appliances that fulfill customer needs along with safety, nice appearance, cost and quality, home appliance companies like Mabe must constantly evolve. Products need regular updates to meet changing customer needs. Sales channels request tailored solutions. And every market comes with its own regulations, preferences and brands. What once set Mabe apart, its ability to customize quickly and serve many different markets, was now difficult to manage. With thousands of SKUs across legacy brands and global regions, Mabe’s portfolio had become increasingly complex. Overlapping products, outdated platforms, and a relentless pace of change made it harder to move quickly and efficiently. The variety that once powered their growth was now putting pressure on operations, making it difficult to scale effectively.

Reduction in product data setup effort

Like many competitors, Mabe had reached a point where product complexity was no longer something they could work around, it was slowing the business down. The reasons were many and familiar to other manufacturers: older products from acquisitions, new platforms added without removing the old ones, and designs created for specific regions or brands. Efforts to cut costs and improve quality added more variation, with parts made for specific SKUs or changes that only applied to high-volume models, without simplifying the rest of the portfolio.

At the same time, market expectations were changing. Mabe was under pressure to bring new products to market faster and respond more quickly to customer needs. But hiring more people wasn’t a realistic solution. The industry was mature and cost-focused, and it was difficult to find the right talent. Adding staff wouldn’t solve the bigger issue anyway, Mabe needed to reduce complexity at the source, not just manage around it. What they needed was a new way to structure their product portfolio, one that could bring order, speed, and clarity to an increasingly complicated business.

To support this transformation, Mabe needed more than just a new process, they needed digital tools to make it work. That’s where PALMA came in. Developed by Modular Management, PALMA became the central platform to manage and apply the modular product architecture across the business. Before PALMA, teams relied on Excel and PowerPoint, stitching together information from CAD, PLM, and ERP systems. The data was scattered, hard to keep current, and difficult to trust. Decision-making suffered, and product teams spent too much time searching for answers rather than building solutions. PALMA changed that. It provided a centralized, scalable product information model that unified data from across the organization. Instead of defining each product individually, Mabe began deriving product configurations from a shared set of modules. This allowed them to populate their product catalogue with far less manual effort, saving time, reducing errors, and improving consistency.

Multiple refrigerator models (ranging from basic to premium)

built from a shared set of standardized components to maximize efficiency and flexibility.

The journey began with a simple yet powerful realization: much of Mabe’s complexity wasn’t valuable to customers. Fragmented product structures and redundant variants were stalling innovation and inflating costs. After researching modular product architecture in the academic world, Mabe partnered with Modular Management to make modularity a reality. Mabe’s transformation was structured around the adoption of modular product architecture, enabled by PALMA, Modular Management’s platform for modularization and product lifecycle support. The approach was comprehensive: start with cooking appliances, develop a shared set of module systems and interfaces, and gradually extend the model across all categories, from washing machines to refrigerators and beyond.

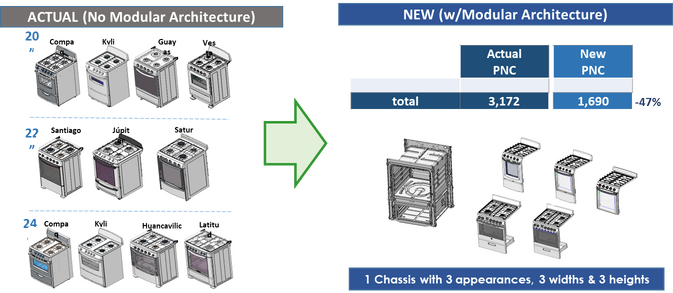

Transition from a non-modular productlineup to a streamlined modular architecture.

These modules were carefully defined with clear strategies for variation, enabling reuse across current and future SKUs.

Instead of designing every SKU from scratch, Mabe used PALMA to configure products by combining predefined module variants. Configuration rules ensured country, brand, and performance-level requirements were built in, like a digital poka-yoke for product development.

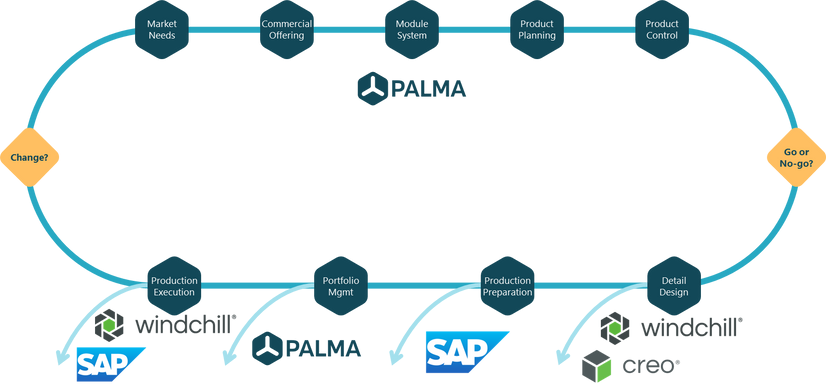

Mabe built seamless integration from product planning in PALMA to engineering BOMs in Windchill PLM, and on to manufacturing BOMs and routing in SAP. No more Excel-based guesswork or manual updates.

The exploded view of module variants in PALMA allowed teams to audit SKUs, understand part usage, and analyze costs in real time. The Product Specification Matrix became the single source of truth, accessible to product managers and developers alike.

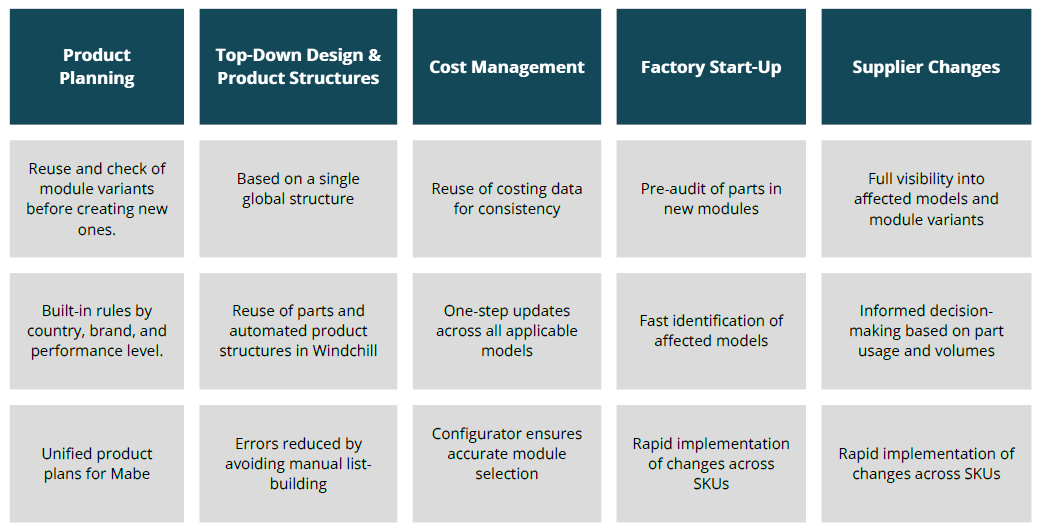

This modular mindset extended even to change management. When parts were updated, suppliers changed, or features became obsolete, the impact across all affected SKUs was visible instantly. BOMs were updated efficiently, and product costing became streamlined using standardized costing data per module variant. Mabe’s transformation wasn’t a one-off project, it became a cultural shift. The modular methodology is now embedded across all new development programs. And thanks to internal champions like M.Mata, former design engineer and now leader of modular architecture, the system has been institutionalized across the majority of Mabe’s white goods portfolio.

Integrated product lifecycle loop, PALMA connects market needs to modular architecture, planning, and execution with smooth collaboration across Windchill, SAP, and Creo.

The impact of this transformation is measurable. Lead time for releasing a new SKU has dropped from one month to just one day. The resources needed to introduce new products have been reduced by 90%, and product maintenance efforts by 80%. Errors and rework have dropped significantly, and country-specific product requirements are applied automatically. With PALMA and modular product architecture, Mabe has built a faster, more agile, and more resilient operation, designed to grow without adding complexity.

With PALMA at the center of its planning process, Mabe treats every SKU as a specific configuration of reusable module variants. When a new SKU is proposed, the team can instantly check whether it can be built from existing modules. If new modules are required, PALMA automatically identifies the gap. The configurator ensures that the right variants are selected based on product plans, enforcing rules tied to country, brand, and performance levels, removing guesswork and reducing manual errors. Today, Mabe consolidates product planning across the company in one system, ensuring visibility, consistency, and faster execution.

Mabe’s design process now starts with a global product structure. Engineers build every new SKU using existing module variants first, creating new parts only when needed. This top-down approach reduces errors and ensures design consistency. Through PALMA’s integration with Windchill, the correct product structure is generated automatically for each configuration, eliminating the need for manual input and reducing reliance on individual judgment or memory.

Cost efficiency has also improved through smart reuse. Costing data from existing module variants is reused in every new SKU where applicable, enabling quick, portfolio-wide updates when prices or suppliers change. The time needed for costing new SKUs has dropped by 80%. The configurator ensures that cost-relevant decisions are accurate from the start, reducing both overhead and the risk of financial

surprises later in the process.

Before a new SKU reaches the production floor, teams can now audit the parts used in each module variant to avoid downstream issues. When a change occurs, such as a new supplier, a part improvement, or a component becoming obsolete, Mabe immediately knows which SKUs and factories are affected. This visibility allows them to implement changes quickly and consistently. The ability to see how each part is used across all SKUs, along with associated volumes, enables smarter sourcing and production

decisions.

"With PALMA, we don’t just launch products faster, we make smarter decisions from day one. It’s clarity, control, and confidence in one platform”.

María Mata

Modular Architecture Leader | Mabe

At the heart of this transformation is M. Mata, a former design engineer at Mabe, current team leader for modular architecture across the entire organization. Through PALMA, she has helped shape how the majority of Mabe’s white goods are developed, documented, and delivered. When working in PALMA, Mary finds the Product Specification Matrix (PSM) to be critical. The PSM provides a good view of their SKU offering, and it is easy to control the variants from the configurator. This has become the location of the official product plan that product managers use to communicate the line-up of SKUs to the development team. Mary and her team are adding the last few module systems to cover the full Mabe portfolio, with full endorsement and support from the business leadership. They are excited to continue the task of improving coordination of activities and information management within the organization. With PALMA,

Mary and her team have been able to improve the speed, quality, and agility of the entire product lifecycle. PALMA has become a valuable tool for Mabe, and Mary is pleased with the progress they have made. Her success story is an excellent example of how using a product management and modularization tool like PALMA can improve the entire product lifecycle for businesses in the manufacturing industry.

PALMA continues to deliver measurable value across critical product development and operations activities at Mabe. In addition to enabling faster SKU releases, reduced effort, and improved consistency, PALMA has significantly shortened the time needed for:

Integrated product lifecycle loop, PALMA connects market needs to modular architecture, planning, and execution with smoothcollaboration across Windchill, SAP, and Creo.

Modular Management's unique approach to transforming customers' ideas into configurable modular systems has been contributing to their growth and profitability for more than 25 years. Modular Management's proven tools for calculating the cost of complexity and estimating the potential of modular kits ensure long-term management support for optimizing modularity and configurability. Modular Management's comprehensive set of methods for defining modular product architectures, known as Modular Function Deployment (MFD), ensures efficient and rapid transitions to modular design methods. PALMA, Modular Management's dedicated software for developing and maintaining modular product platforms, enables users to realize the full potential of their investments in optimized modular product architectures.

Modular Management was founded in 1995 and today has offices in Germany, Japan, the United States

and Sweden. To learn more, visit Modular Management at www.modularmanagement.com.

75% less part numbers

50x market offerings

Quotation lead time reduced from 7 Days to 1

40% less part numbers

25% shorter time to market

1+ billion in added shareholder value

50% reduced design cost

25% faster construction time

50% less on-site indirect cost