Market-Leading Position with Modular Design

Inspiration for Hardware Design

Case Story

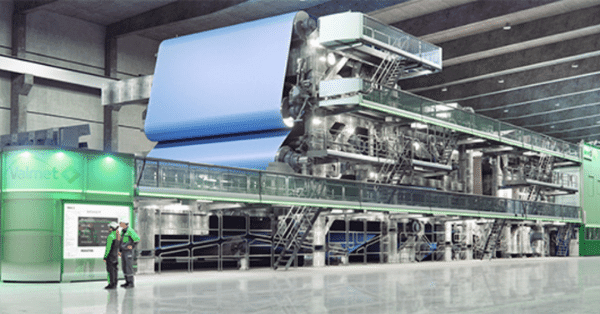

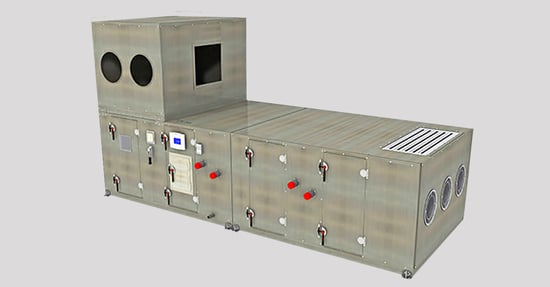

Trane Commercial Systems

Trane Performance Climate Changer Air Handler

Trane Commercial Air Handlers faced several challenges, including rising costs, requirements for more energy-efficient products, older product families, challenges to product leadership with competitors’ new features and options, a proliferation of parts, and high product and systems complexity. Operational improvements through lean and process automation were effective yet insufficient, and the company, as a long-term market leader, was finding it hard to sustain price premiums and market share.

In this situation, Trane embarked on a modularity program that delivered dramatic results:

- 58% reduction of part numbers

- 15% reduction in overall product cost

- 10% reduction in the cost of operations

- 7% reduction in direct material costs

- 50% reduction in development time.

The new line of air handlers also became the most energy-efficient on the market, achieved lower levels of humidity compared to competitor products, and reduced energy consumption by up to 30%. Customers were offered lower acquisition costs, more product variety (50% increase) and lower operating costs, and Trane successfully defended its market-leading position with modular designs.

Company Description

Trane has 8 billion USD in annual revenue within the commercial, industrial, and residential heating, ventilation, and cooling (HVAC) markets. They supply HVAC systems, dehumidifying, air cleaning, and building control products, along with parts, service, and financing.

Business Situation

Long-term product leader no longer commanded a price premium and was losing market share

Current product did not meet market requirements for energy efficiency and overall cost

Operational improvements through Lean and process automation alone were not sufficient

Modularity Results

Expanded range of product offeringRefocused on true customer value

Combined two product families

Reinvigorated Lean activities

Increased impact of automation

Measurable Improvements

58% reduction of part numbers15% reduction in overall product cost

10% reduction in the cost of operations

7% reduction in direct material costs

50% reduction in development time

Full Story

Business Situation

Commercial heating, ventilation and cooling (HVAC) products have a lifetime of around 20 years, and the technology has evolved slowly but steadily over the years. Large and complex HVAC systems are specified for individual customers through a direct sales network, approved by engineering, built to order and installed by a system integrator.

In 2007, rising energy costs and conservation initiatives were driving demand for more energy-efficient products and for retrofit and refurbishment of existing, less-efficient systems. Trane was the market share leader in North America and was working to grow in other regions by leveraging their reputation for reliability, flexibility, and product innovation.

Market dynamics caused many of the commercial HVAC products to become commodity-like with pressure on even the complex ones to reduce price and cost. The average age of Trane Commercial Systems Air Handler products was relatively old by industry standards and many new features and options were being introduced by competitors. They needed to make significant investments to update the product portfolio with value-added features that would help them to stay ahead of the competition.

Trane had always been a strong company with good profitability and long-term organic growth averaging 7-8%, but they were looking for ways to continue fine-tuning their operations. In the years preceding this case, the product teams had been deploying Lean techniques and component rationalization. These initiatives saved money, but in many situations Trane discovered that additional improvements were limited without changes to the existing product design.

One team in Commercial Systems uncovered that hundreds of different motors were being supported by the engineering and operations system. As the team examined the issue, working motor-by-motor, they always found good technical reasons why each motor was used. In the end, very few motors could be eliminated.

Product Marketing & Management

When the modular climate changer product family was introduced in the 1990’s, it quickly became the leading air handling product in the market. Not only was it the performance leader, but it could be configured to meet the needs of very specific applications. This was accomplished through a series of functional building blocks that could be manufactured separately and assembled into a complete system. This product strategy paired well with Trane’s technical, relationship-based selling methods, and for many years the building contractors and HVAC engineers preferred to work with Trane.

As demand for the product grew, Trane invested in an automated order engineering process that helped create the engineering drawings needed to manufacture and assemble each individual system. This decreased the time and errors when the engineering team to release an order. Eventually, they also invested into automated production systems that could use the data from the order engineering process to produce accurate components even though they may have never been built before.

In the years leading up to 2007, it was becoming apparent to the marketing team that the Modular Climate Changer product family was reaching the end of its product lifecycle. Competitive products introduced in the market had more of the features that were in demand by building managers and occupants. Opportunities for reducing costs were also greatly diminished, and Trane was faced with a large new product development effort to reinstate their product leadership position.

Product Design & Engineering

The customer-facing modularity of the product was a continual source of activity and challenge. The ongoing product engineering team had strong capabilities to deliver and maintain the current family of products. They were occupied with customer orders and the maintenance of the current air handler product family. Components such as coils and filters were constantly adapted to deliver exactly what was agreed to by the sales team and customer.

According to Trane’s Product Engineering Director, Jim Wendschlag, “Trane’s central station air handling units expand a wide range of unit sizes and offer a multitude of features and options to meet the different needs of many building types in many climates. This product flexibility over time led to the proliferation of thousands and thousands of parts and high product and systems complexity and associated costs.”

Improvement efforts for years were focused on the optimization of the order engineering process and the automation of the documentation needed to build the large range of product configurations. Product design data such as bill-of-materials fell into a lower priority and were kept in spread sheets rather than vaulting, MRP or PLM systems.

As with many continuation engineering teams, they had little time for new product development, and the growing list of product updates sought by the marketing team required the broader involvement of Trane engineering resources. Large new product development projects typically required the commitment of resources for 36 months before any new product entered the market. For many years the air handler project waited to make it to the top of the list of investment priorities.

Product Operations

A skilled and ambitious operations team championed many investments that improved the efficiency of providing the large range of product configurations. In addition to the removal of waste by deploying the principles of Lean, they looked to process automation to off-set the product complexity that was carried through to the manufacturing plant.

Many improvements were made through the years but the problems of product complexity remained. Flow through the plant was often halted because a special operation needed to be done on one system. In 2007, the air handler product family comprised of the M-series indoor and T-series outdoor systems were built on separate manufacturing lines. Near the top of the list of improvements for many years was the rationalization of these two manufacturing lines. The two systems shared many components, but the merging of the casings required changes to the design of the products.

Goal for the Modular Architecture

The leadership team at Trane Commercial Systems was faced with the challenge of how to invest into a new family of air handler products. They wanted to maintain and grow market share by re-establishing their product leadership position.

With a long-standing focus on cost reductions and maintaining levels of efficiency to support the wide range of product configurations, Trane sought to develop a family of products with a new set of innovative features. The family would be delivered from a Modular Architecture that could be efficiently updated during the product lifecycle. They also wanted to preserve and enhance the investments that had been made in streamlining and automating the manufacturing plant.

Revenue Growth

Implementing the modular architecture for the air handler product family promised to reduce the time for new product development by adding more detailed up-front planning and the ability to simultaneous develop and launch a variety of different modules at different times. The goal was a 25% reduction in time for major changes and 33% for smaller updates. They also planned to reduce the order-to-delivery time. For large products delivery time was expected to be reduced by 50%, and smaller products were to be reduced by 63%.

Trane also sought to increase their ability to maintain their leadership throughout the lifecycle of the product. The underlying speed of development would help, but they also needed the ability to introduce minor features without impacting the majority of the product design. By creating a standardized interface, for example between the air handler and the control system, it would be easier to introduce new features and integrate the controls with new and existing systems.

Profitability Improvement

Along with faster development of new products and features, Trane planned to achieve a reduced level of investment to make changes and updates to the product family. This would allow them to make more frequent, smaller changes and to continuously improve product operations and profitability. A 10% reduction in the cost of operations was projected, and the cost of materials would be reduced by 7% through more efficient designs, higher volumes and planned purchasing. Trane also intended to integrate the separate indoor and outdoor versions of the product into the same architecture and to share interfaces to the casing.

The cost of providing such a wide range of product configurations remained high even with process automation. Trane looked to Modular Architecture for a way to maintain the customer-perceived flexibility of the current product family while lowering overall costs. As a working goal, they established a key performance indicator that said 80% of orders would be 100% configured from standard modules while the remaining 20% would use 95% standard modules.

Architecture in Action

An example of a higher level of product assembly is the external casing that encloses all of the internal components and allows air to enter and exit at specific locations. While developing the Modular Architecture, the team at Trane discovered that the casing is a key technical solution for an air handler. It embodies many of the properties of the product and impacts many of the different ways customers perceive the value of the product.

This realization established new priorities in the design of the product to maximize the effectiveness of the casing. In fact, large capital investments were made to fully automate the forming of the sheet metal and the installation of insulating foam. The casing now contains interfaces to most other modules and the specific casing variant is chosen once the configuration of the rest of the product is completed. A unified casing is designed and manufactured for each product combination. The automated equipment takes care of the manufacturing complexity.

The development of the modular architecture also allowed Trane to address nagging customer complaints about the availability of replaceable air filters. The discipline learned and momentum gained in creating standardized interfaces throughout the product allowed them to tackle the challenge of integrating standard filters. As a result, filters are selected as off-the-shelf components, reducing the time and money for customers to procure a replacement.

Business Result

Product Marketing & Management

At the time of launch, the new Trane Performance Climate Changer Air Handler (see Figure 2) was the most energy-efficient air handler in the market. It provided overall better comfort for the conditioned spaces and obtained lower levels of humidity. Energy consumption and the corresponding emissions were reduced by up to 30%. Customers saw a lower initial cost and additional savings during long-term operation.

Trane changed the basis of sales discussion and competition to focus on the value of an overall higher performing system. Many of these facets of performance were new ones that were not previously exploited within the market and were discovered during the process of developing the Modular Architecture. The new product family maintained the leadership position that was once held by the legacy Modular Climate Changer.

By including both the indoor and outdoor product families within a single Modular Architecture, Trane improved their efficiency beyond what they could have done with each individually. The number of physical sizes available to customers was increased from 18 to 26, and they increased the number of new and available product options. The automated order engineering process became less critical to the delivery efficiency of the product because most orders became pre-determined configurations within the architecture.

In the words of Jim Wendschlag, “This new approach, together with innovative engineering systems design, is providing us with opportunities for significant direct and indirect labor efficiencies and a much faster product change through the product life cycle.”

Product Development Engineering

The time to develop the first in the family of new air handlers was decreased from 36 to 18 months including the upfront time to develop the modular architecture. Even with portions of the new and old product in the market, this trend was expected to continue because the vast majority of the new products were now being configured from a pre-defined set of module variants. Along with a larger set of completed designs, these variants had pre-determined operational plans that would reduce the engineering team’s involvement in fixing manufacturing and sourcing issues.

The team saw a 58% reduction in the number of parts needed to be created and managed in order to deliver the new air handler product family. This was in addition to the underlying efficiency gained by combining the two separate families. From Jim Wendschlag perspective, “We were helped to develop a new approach to modular design focused on part count and complexity reduction while adding to the product flexibility for the customer.”

Product Operations

Trane initially achieved a 15% efficiency improvement in the final assembly of the new family of air handlers through the application of Lean and process automation. These savings were previously unavailable with the legacy product design, but now the manufacturing strategy was an integral part of the underlying product structure through the Modular Product Architecture. The architecture also enabled many common parts to be shared across the product family resulting in lower material costs and more efficient supply strategies.

The operations team also gained a new focus on the product performance characteristics that mattered most to customers by collaborating in the development of the architecture. The architecture was intentionally structured to accommodate process automation at a higher level of product assembly where the benefits of consistent and repeatable processes have a larger impact on customer satisfaction.

“The product has been well received by our customers and I believe will be a big win for us when we are all done. The quality has been outstanding with our warranty costs and defects per unit exceeding the program goals.” says Jim Wendschlag.