Accelerate Value Creation through Modularization

Our Customers Achieve Unmatched Outcomes

Whirlpool

How product architecture increases the number of variants, reduces costs and enables a rapid refresh of models – building a bridge between strategy and results.

Husqvarna

Acquisitions, regional product variations and low-cost competition all meant Husqvarna needed to find new ways to rationalize part numbers, lower costs and globalize product design.

Johnson Controls Hitachi

How market segmentation clarifies customer needs, links company strategy and drives product planning.

Trane Commercial Air Handling

How a product architecture strengthens product leadership, reduces cost and goes beyond lean and process automation.

Bosch

Bosch Home Comfort’s heat pump businesses faced a number of challenges. The company implemented a modularity program and achieved dramatic results.

Sidel

Reduce costs, increase market share and increase price premiums through a new modular product architecture.

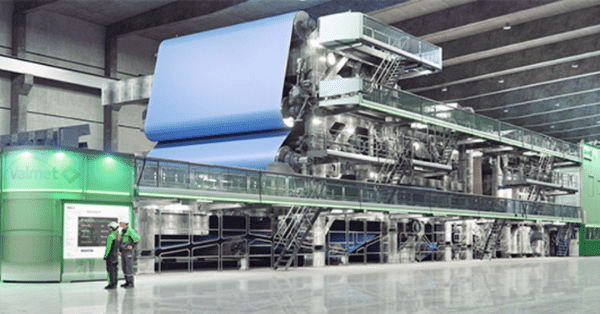

Valmet Paper Machine

Valmet’s management team has made modularity a cornerstone of its operation’s development, including the digitalization and “fit-for-purpose” visions.

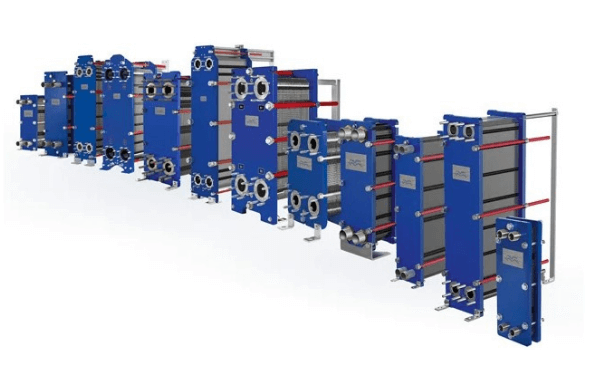

Alfa Laval

Alfa Laval supply gasketed plate-and-frame heat exchangers. Two key enablers for their cutting-edge order-to-configure process are configurability and an information model.

CommScope

ESAB

Edscha Trailer Systems

How a modular product architecture embeds customer needs, drives product planning and delivers business results.

MTS Systems

How a product architecture reduces unique part numbers with 90%, lowers customer project costs and shortens lead times.

Dynapac

How a product architecture helps reduce time to market for local variants, strengthens central product ownership and reduces cost.

Guldmann

Increased the number of variants, reduced cost, and enabled growth in new markets – building a bridge between strategy and results.

Dellner

Dellner offers production and after market services for train connection systems. Find out more about their customer-centric design and modular product architecture.

Peab

Peab is one of the largest contractors for building and home construction in the Nordics. Their modular product architecture enables flexible, affordable and attractive housing.

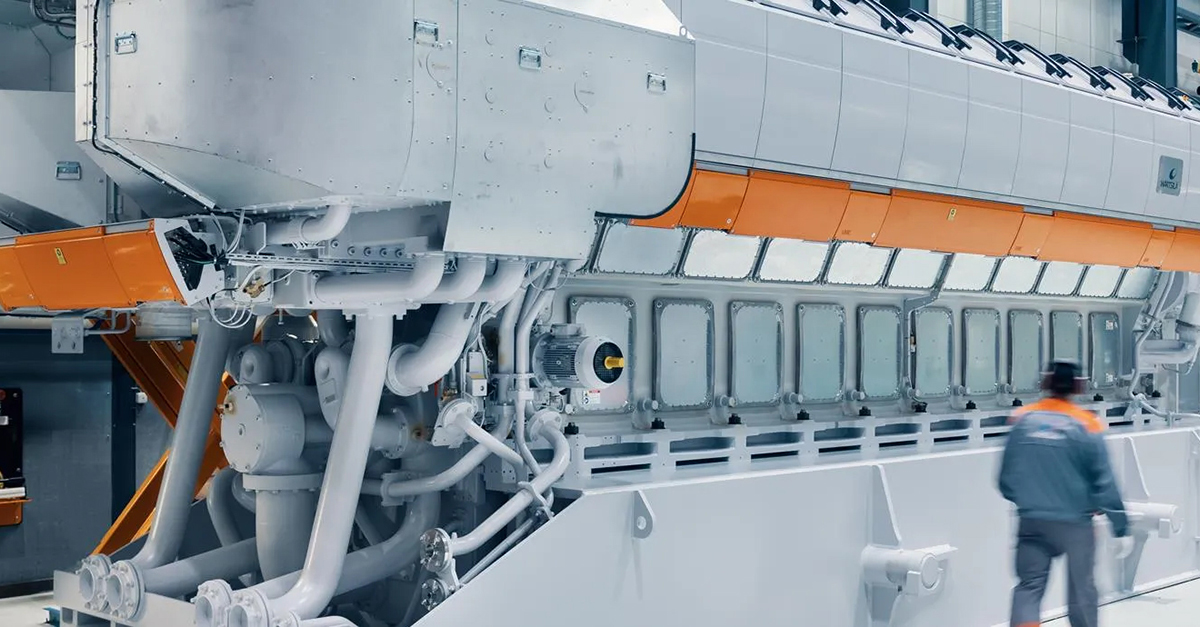

Wärtsilä

How was Wärtsilä able to reduce complexity and accelerate value creation for the world’s most efficient engine?

%20(1).png)